If this is your company, CONTACT US to activate Packbase™ software to build your portal.

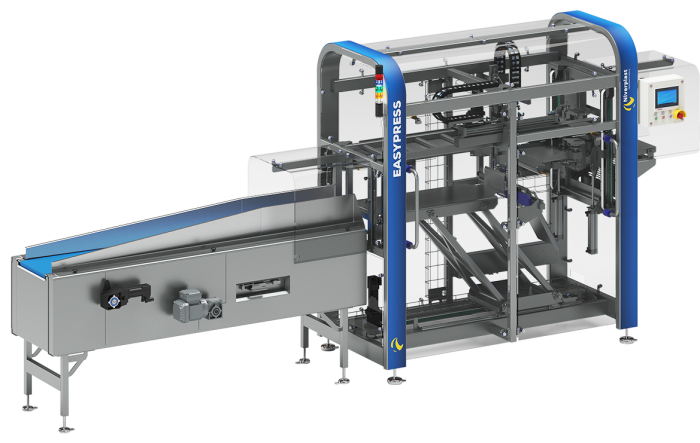

As a Dutch manufacturer of packaging machines, we distribute our machines all over the world. The machines we produce are mainly known for the bag-in-box principle; automatically placing bags into boxes or crates. But we also support other packaging operations that can be done by machine, stand-alone or in line. The solutions that we develop can be used in various markets, such as the bakery, meat and fish industry, or the moulding industry. This time we were challenged to develop a machine for laundry packaging. Challenge accepted: Meet our EasyPress!

"The request for a new kind of machine for packaging laundry came practically from next door! A large industrial laundry in the north of the Netherlands, asked us to think about their current way of packaging and the possibilities to improve it. So that's what we did!"

Erwin Smit - Niverplast

Automating industrial laundries

A market unknown to us until recently, was the laundry market. We got in touch with an industrial laundry who had a great desire to take the automation of their packaging to the next step and simultaneously compressing it. Of course with the aim to achieve savings, but not only in labor and operations, but mainly in volume. After discussing the wishes and requirements, we made them a concept proposal. A few months later, the development of the first laundry packaging machine was a fact: the EasyPress. Good for cost reduction, but also an environmental improvement.

The new Easypress; how the machine works

The EasyPress compresses laundry into compact stacks. The stacks are automatically fed onto a conveyor belt, after which the machine compresses them into a much smaller bundle. The stacks of laundry then slide automatically into a plastic package and got sealed by the machine. The space gained by this is over 60%. In this way, more textiles fit on a container, so larger numbers fits in the truck.

Turn the tide with plastic

Plastic packaging has the image of being unsustainable. However, when it comes to sustainability, you need to look at the entire process. How does it work in the current situation, which process steps and raw materials are needed and what impact does it have? Then you start weighing options and calculating them.

"Of course there are disadvantages to plastic, but if you handle it carefully and make sure it doesn't end up in nature, it is a very sustainable way of packaging. After all, plastic is infinitely recyclable. In addition, it takes less energy to extract and produce it than paper, for example."

The biggest sustainability benefit of this machine is achieved by simply fitting many more stacks on a roll container. This means less internal transport, less packaging material, less storage, less loading and unloading and fewer transports. This new way of packaging can amount to 140,000 fewer kilometers needed to be driven on an annual basis. That saves a lot of CO2 emissions!

Want to know more?

In March 2023, the very first EasyPress will be installed at the customer's premises. If you are interested in this machine, you are welcome to visit the production site in Nijverdal (NL). If you wish to attend, just get in touch. We are happy to have you!