Join Doctor Pack at Europe's leading packaging and drug delivery event, Pharmapack by CPHI, at the Paris Expo (Hall 7.2/Booth A105), Porte de Versailles, Paris, France. Since 1997, Pharmapack has been the leading European event for pharmaceutical packaging, drug delivery, medical devices, and machinery.

Machinery & Automation Packaging News

Company’s fully automated UDS Vial Filling & Assembly System can produce up to 100 unidose nasal spray devices per minute, and incorporate a variety of sophisticated inspection parameters.

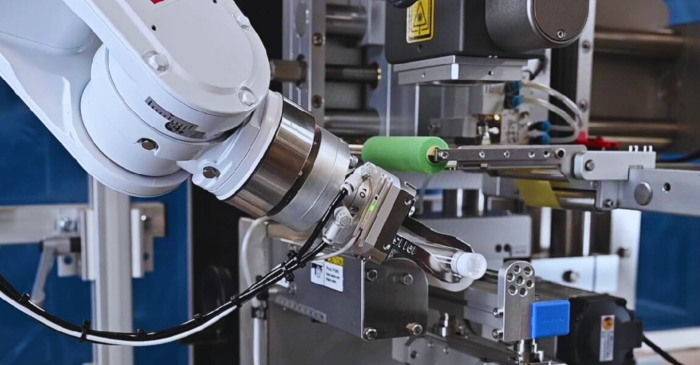

The newly developed 211RHC labeling cell features the world’s smallest fully integrated servo gripper and performs up to 25% faster than comparable semi-automatic machines.

Mold-Masters®, a leading developer and supplier of hot runners, controllers, auxiliary injection, and co-injection systems, has optimized the design of its PET-Series hot runner system to reduce its stack height to 260mm on systems with 72 cavities or less using standard components.

Discover the potential savings offered by the in-house production of spouted pouches. SÜDPACK, SN Maschinenbau and MENSHEN are breaking new ground together in sustainability and economic profitability. The partnership comprised of three industry leaders is setting standards. Reduce your packaging costs by producing your own stand-up pouches – without making any compromises when it comes to quality or safety.

Antares Vision Group has introduced a non-invasive, inline pressure measurement system providing reliable, high-speed inspection for beverages in glass and plastic bottles.

Welcome to the future of packaging innovation at Toly! We are thrilled to share a groundbreaking development that will elevate our manufacturing capabilities to new heights. Toly has recently invested in the cutting-edge Novapax Injection Blow Moulding (IBM) machine, a game-changer in the world of plastic packaging production.

Aranow, a leader in single-dose packaging solutions, offers you some guidelines to sort through the different packaging machinery manufacturers on the market. With this guide we recommend you to pay attention to these 5 points that will make the difference, and will help you in the difficult choice of choosing the ideal manufacturer.

he machines we produce are mainly known for the bag-in-box principle; automatically placing bags into boxes or crates. But we also support other packaging operations that can be done by machine, stand-alone or in line. The solutions that we develop can be used in various markets, such as the bakery, meat and fish industry, or the moulding industry. This time we were challenged to develop a machine for laundry packaging. Challenge accepted: Meet our EasyPress!

Ishida Europe is launching a tray sealer which the company claims is breaking new ground in terms of both its performance and environmental benefits. The new Ishida QX-500 has been developed following detailed feedback from Ishida’s global customers and partners.

.jpg)