If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Easypack is an innovative packaging system which does not use glue or shrink wrapping to pack together several products. It is one of two multipacker systems on offer by ACMI. Easypack forms the packs using special, fully printable and customizable bands of extensible material called "sleeves" that are placed around the products. The group of products formed in this way is called a multipack.

Easypack is used in all those cases where it is necessary to pack together two or more products to form packs of 2, 4 or 6 pieces which are named respectively bipack, fourpack and sixpack. The machine reaches a speed that can be safely inserted into a modern bottling line and performs the same function of the shrink wrapper but using different technology, with considerable advantages in terms of costs and maintenance. Therefore, the machine represents an interesting alternative for the production of innovative packs that meet the needs of the modern consumer both in terms of practicality and external appearance. The insertion of the machine within the line saves space, too.

The main advantages of thie Easypack system are represented by the great packaging flexibility that may vary from the pack of two products up to that of six and by the possibility of complete customization of the sleeve that can be printed in all its extension increasing the effectiveness of communication at the point of sale. From a technical point of view the machine does not use glue or heat which is beneficial both for the environment and the workplace.

In addition, purchasing, running and maintenance costs are considerably reduced, too. Finally, it is important to point out the simplicity of operation, the reduced maintenance and the rather limited overall dimensions. Thanks to these features and the new packaging concept Easypack introduces, the world of packaging can count on a revolutionary system that meets the main needs of modern production, one of which is the ability to regularly innovate product packaging.

Easypack can be connected directly to the Viper handle applicator, without the need of any intermediate conveyors, forming an exceptional system in terms of space occupied and functions carried out. The application of the handle, which can be fully printed and customized, facilitates the transport of the pack to the point of sale by the final consumer and can be applied to all types of packaging: bipack, fourpack and sixpack. With this configuration Easypack becomes an extremely functional machine, able to receive the labelled product and pack it for the final palletisation phase.

Including ACMI's Easypack in a packaging line means designing a compact, flexible, reliable and efficient system.

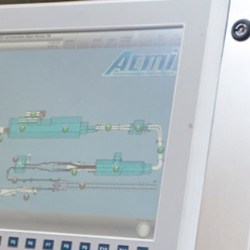

ACMI is an Italian company specialized in the production of high technology bottling and packaging lines and based in Fornovo Taro, in the province of Parma.