If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Coelsanus case study: Two jar lines (B-C) of 1,900 jph with different formats

A jar line (A) of 2,700 jph with different formats

A tin line (D) of 1,900 cph. Formats: from 1 to 5 kg

In the province of Venice (Italy), the Coelsanus SpA factory is situated which is one of the most important Italian manufacturers of pickled foods.

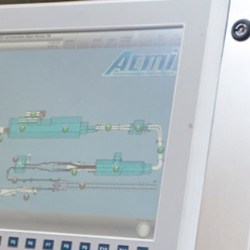

ACMI dealt with an end of line that handles four production lines through a sophisticated palletisation system. Jar lines B and C are independent and run by two dedicated palletisers, whereas lines A and D are in the multiliner configuration and converge on a single palletiser.

On jar lines B and C, ACMI installed two fixed openable platform Rasar P135 palletisers with an hourly capacity of 3,000 packs, and on lines A and D a dual infeed Rasar P136 was positioned in the multiliner configuration. In particular, it should be noted that line A is a “jar” line, whereas line D is a “tin” line with weights ranging from one to five kilogrammes. The production speed is 2,700 packs per hour for line A and 1,900 packs per hour for line D.

The multiliner palletiser can work both formats independently or handle them simultaneously alternating the two pallets depending on product availability. In this way, a constant palletisation speed is always guaranteed independent of the type of product available, whether jar or tin.

The full pallets coming out of the three palletisers are conveyed to a single rotating pallet stretch wrapper through a wire-guided shuttle. The shuttle operates according to specific signals indicating at which outfeed of the three palletisers the pallet of products is available.

Made in this way, the packaging system allows for space optimization while ensuring reliability and high performance.