Public

Aptar CSP News

Aptar CSP Technologies Documents

Aptar CSP Technologies Locations

Aptar CSP Technologies Videos

Subsidiaries

Maxwell Chase Technologies

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

Aptar CSP Technologies, part of AptarGroup, Inc., and a leader in active material science solutions that ensure product protection, extend shelf life and improve user experience, was awarded a $19 million contract from the U.S. government. This award will support expanded domestic production capacity for the company’s proprietary Activ-Film technology, which is used to protect and ensure COVID-19 test kit integrity and accuracy.

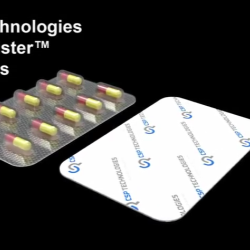

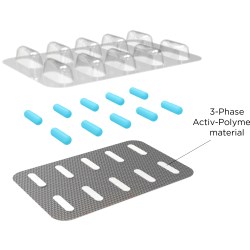

Aptar CSP’s Activ-Film technology is seamlessly integrated into diagnostic dipsticks and lateral flow cassettes to protect diagnostic tests from moisture or other environmental degradants that can impact test integrity and result accuracy. Activ-Film leverages Aptar’s proprietary 3-Phase Activ-Polymer platform technology to provide broad spectrum, custom-engineered protection delivered in a variety of configurations. The technology is formulated to adsorb a specific amount of moisture and other compounds at a customized rate, creating a consistent microclimate throughout the supply chain.

John Belfance, President of Aptar CSP Technologies said:

“We are honored to partner with the U.S. government to deliver a much needed capacity expansion of our technology to support COVID-19 antigen at-home self-tests.”

The contract, funded by the 2021 America Rescue Plan Act 3080, provides for procurement of equipment and machinery needed to increase production of Activ-Film material at Aptar CSP’s Auburn, Alabama plant. Completion of this effort is expected in early 2023. Aptar CSP’s active material science platform technology is currently used to protect a range of electrochemical, lateral flow, and molecular diagnostic test kits on the market today.

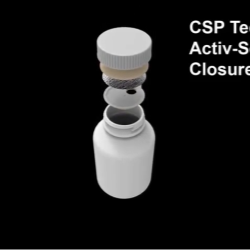

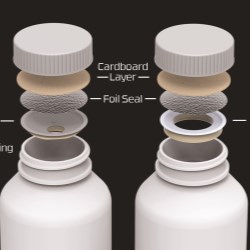

Additionally, the technology is utilized in a variety of configurations for a wide range of application fields such as oral solid dose drugs, transdermal drug delivery, medical devices, and probiotics. The technology can be engineered to adsorb moisture, scavenge odor, oxygen, or VOCs, emit aromas, or reduce pathogens.

Badre Hammond, VP Commercial Operations, Aptar CSP Technologies said:

“The continued need for testing to mitigate the spread of COVID-19 along with pandemic-driven supply chain challenges has led to increased demand for our active material science solutions in the diagnostics space. Building on current capacity, this funding will enable current and future partners to expand access to reliable diagnostic solutions for infectious diseases.”

.jpg)

.jpg)

.jpg)

.jpg)

.png)