If this is your company, CONTACT US to activate Packbase™ software to build your portal.

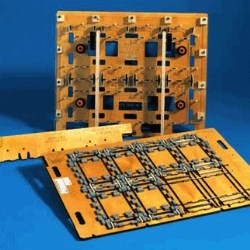

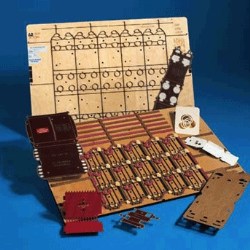

Since Arden Dies introduced Speed Strip technology to Britain in 1992, its use has grown to out-sell conventional strippers by a staggering ratio of 10 to 1. The system has caught on so successfully that it is now used by almost all progressive carton producers throughout Europe.

How it works

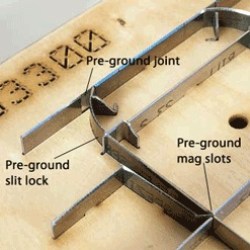

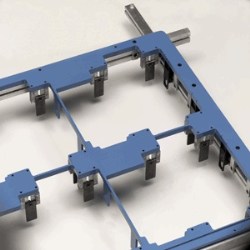

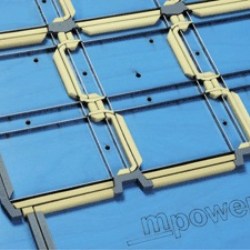

The unique design of the patented Speed Strip claws in the upper tool forces waste board through the specially designed apertures in the lower tool without the need for under action pins. By eliminating the need for under action pins, Speed strip saves time on machine setting and possible waste build-ups that may hamper production continuity. With less requirement for under action pins, expensive stocks can be reduced and manpower presently tied up building lower units to meet production schedules can be used more efficiently.

Advantages

- Reduction of under action pins

- Quicker machine make ready time

- Less machine stoppages

Ensuring Performance

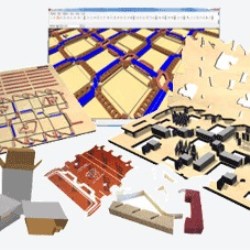

To maximise speed strip performance, Arden Dies offers on-site training covering setting up, machine running, chain register, board caliper and storage. On press technical support is also available when required. Arden Dies views each layout to ensure the speed strip will meet with the customer’s expectations.

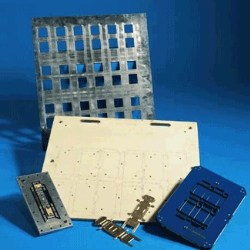

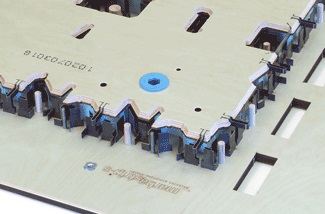

Steel Plate Strippers

Steel plate strippers As shown opposite, steel plate can be added to the lower tool. This will aid strength on strippers that may have been left weakened by large or closely grouped apertures. Added benefits include a sharper profile, making stripping more positive on difficult apertures. It requires no routing and maintains a harder wearing surface throughout the stripper’s life. Speed strip units can be supplied with the necessary fixings to ensure the swiftest possible transition to machine.