If this is your company, CONTACT US to activate Packbase™ software to build your portal.

From printing to cutting and gluing, all stages of manufacture are dealt with on-site in our fully fitted production plant, placing us at the envy of our competitors.

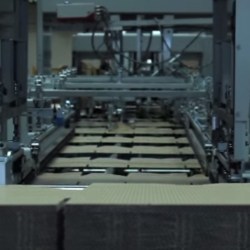

We are proud to boast an array of the industry’s most advanced modern machinery from industry leaders such as EMBA, BOBST and J&L, all of whom are renowned for product reliability and innovation within the industry. Specialist facilities include –

Emba 245 QS Ultima - The world’s most advance corrugated board conversion machine. Since installing this piece of equipment we have seen a 20% improvement in pallet utilisation. For full details about the Emba, read our Blog Post.

Multi-point gluing – We use two types of in-line fold gluers that give us the ability to glue an array of board sizes in varying levels of structural complexity. The versatile BOBST gluer can accept a feed of 1400m, whilst smaller feed sizes are glued using the specialised J&L machine.

Die-Cutting – Our BOBST flatbed die-cutting facilities are exceptionally reliable and ensure the finest quality of outcome. The efficiency of this process has allowed us to cut costs, reduce processes and thereby increase plant productivity.

Efficiency is Key

We are constantly striving to improve the efficiency of our manufacturing processes here at Atlas and our recent investment in facilities reflects this. We aim to ensure that our systems are as cost effective, environmentally friendly and time effective as possible. Furthermore, all of our machines have duplicates so that we can guarantee that projects aren’t delayed in the event of a mechanical breakdown.

We separate large and small scale projects between our main plant and our smaller ‘Box Shop’ production facility. This is so that we are able to dedicate the same care and attention to all sized jobs.

Doing our bit for the Environment

We like to keep waste to a minimum but we’re never going to eliminate it completely, and because we’re so passionate about reducing our impact on the environment, we have built an industrial scale recycling system underneath the production plant. This closed loop system captures waste board and efficiently packs it into tightly pressed card bails which are recycled for reuse.