If this is your company, CONTACT US to activate Packbase™ software to build your portal.

'In God We Trust' is the official motto of the United States; but as God is not a member of the Society of Plastics Engineers (SPE) or the Australian Institute of Packaging (AIP) we need to bring our trust down to earth.

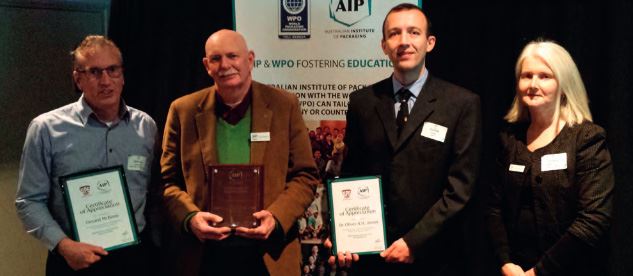

Craig Benson Chair of SPE on behalf of both organisations introduced the guest presenters Gerard Mckone Business Development and Technical Manager for Clariant (New Zealand) Pty Ltd and Dr Oliver Jones from the School of Sciences at RMIT University. Each in their address came to conclude that trust is vital when addressing the issues relating to packaging of food.

Gerard Mckone immediately advised that in New Zealand there is trust between humans and sheep but not so for possums. He continued with a highly technical and informative address entitled bringing packaging to life through additives.

Clariant offers a broad range of specialty additives with a variety of effects and possibilities to modify polymers for different applications: - light stabilisers, processing stabilisers, antioxidants, sulfur-containing co-stabilisers, metal deactivators and antistatic agents.

Highlighting that the global population is expected to be around 9 billion in 2050, and that we are already using resources that would support our current populations plus half as many again, which is not sustainable.

He stated that the global packaging industry holds the key to long-term sustainability. Global challenges such as resource use leads to innovation. Innovations in sustainability and the capacity to regenerate are the key drivers.

The buying power and wealth in emerging countries are growing, which increases demand. This is happening in the basic life supporting resources, fossil energy, minerals, water, renewables, nutrition and land. But environmental issues often countermand advances made by industry.

Clariant is looking beyond today's boundaries in the areas of changing lifestyles and the ageing population. In other words what is beyond the 'now society'! Then how to feed the future in the now and emerging markets which to a high degree are driven by convenience.

They are continually searching for emerging technologies such as:

- Surface effect solutions known as slip additives. Packaging surfaces often exhibit high friction leading to problems during manufacture, processing and end-use.

- Surface effect solutions known as anti-block additives. Blocking results from the adhesion developed between two smooth layers of film or sheet placed in contact with each other. (Technicians were referred to the work of Dutch scientist Johannes Diderik van der Waals.)

- Surface effect solutions known as anti-fogging. Fogging occurs in food packaging films when there is a temperature difference inside and outside of the packaging. Anti-fogging additives can prevent soggy unpalatable food.

In his 'trust us' recital Gerard stated "We do not compromise... Safety first Risk Management is important". He said that consumers can have the confidence and knowledge to use Clariant materials which are 100% compliant to global standard and local regulations.

He gave a quick overview of the company product stewardship and then addressed questions from the audience. Out of these came the proposal that there is still a major gap in the ability to produce non fossil fuel based materials, due to food and packaging seeking the same agricultural based raw materials. Much has been written in recent years about migration of packaging materials into food, and this was the topic addressed by Dr Oliver Jones. He commenced with definitions of issues to be addressed.

Food contact materials (FCM) are either intended to be brought into contact with food, are already in contact, or can reasonably be brought into contact, or transfer their constituents to the food under normal or foreseeable use. Examples include food and drink containers, food machinery, food packaging materials, kitchenware and tableware.

Non-intentionally added substances (NIAS) are chemical compounds that are present in a material but have not been added for a technical reason during the production process. NIAS originate from break-down of food contact materials, impurities of starting materials, unwanted side-products and various contaminants from recycling processes. Sources of NIAS are the breakdown of products caused by impurities or contaminants from recycling processes. Degradation of polymers or additives is interesting as there are 6000 compounds approved as additives to plastic in Europe and USA.

Oliver noted there are many materials in packaging that can contaminate food. The one most publicised is where boxes for cereals made from recycled board leached inks and oils into the food. Contaminates could have come from glues in tape used to seal the previous packages or the inks used for graphics.

The law of unintended consequences came into play when we heard about inert jute material woven into bags for foods such as coffee beans. To make jute pliable to weave the material it has to be treated with mineral oils. These in turn have been found to leach out in some circumstances. The subject of Epoxidised soybean oil (ESBO) and Bisphenol A (BPA) came into focus and much science was used to explain the manufacture and application. While ESBO itself is not thought to be present at high levels in food, the reaction with PVC creates oil with a hydroxy group and a chlorine atom bound to a fatty acid. Such a compound has never existed in nature.

Dr Oliver remarked that BPA had been given an inordinate ‘going over’ for many years yet no clear evidence has been produced to say that it is a health hazard. BPA replacers such as BPS and BPF can still leach out, but again evidence of food contamination is scant. Oliver thought it was interesting to wonder why there are so many papers on BPA that show nothing unless unrealistically high doses are used, when a huge scandal might be around the corner on one of the many unstudied substances? (Perhaps buzz-word chemicals are easier to publish.)

Migration is the mass transfer from an external source into food by sub-microscopic processes and can cause degradation of food ranging from taste to illness causing. It can happen anywhere along the manufacturing or supply chain. Examples of the jute bags and cereal boxes were again noted.

A chart showing the regulations applicable under EU rules resembled the management hierarchy of a major company. The various subsections of the regulations attached to Framework Regulation (EC) No 1935/2004 were shown but not discussed in any detail.

To be fair it is likely that this would have needed far more than the 20 minutes speaking allotted; Oliver's point was that legislation on NIAS is increasing and is something the industry should at least have on their radar.

In summary we found that more than 6,000 different manufactured substances are now approved for use as packaging in the US and Europe alone. There are many NIAS which can migrate into food from FCM but many of these chemicals are not structurally or toxicologically characterised, but are present in much higher concentrations than pesticides and other well-known problem chemicals.

Regulations on food packing primarily covers only the starting materials (the FCM) and not potential reaction products (the NIAS), such as those produced from resins. Health risks are unknown but regulations are a continuing process. In his trust scenario Dr Oliver proposed that many consumers who support organic foods place their trust that non-intentionally added substances are safe, but distrust chemicals such as pesticides that are highly regulated and always under scrutiny.

One can imagine that an event where home produced food is sold that any package that is available will be given to the consumer. So again the question is who do YOU trust? The lingering audience was abuzz with questions and discussions indicating that they at least trusted what our professional presenters had spoken about.

Written by Michael B Halley FAIP

.jpg)