Axium Packaging delivers operational excellence, innovation, and rapid commercialization to the world’s leading personal care, home, food and beverage brands. Axium Packaging invests heavily in the latest molding technology to keep our clients one step ahead. Uniform production platforms across all facilities provide consistency and business continuity, support consumer testing and soft launches, offer flexible surge protection, and minimize inventories.

Axium has invested heavily in the latest molding technologies. Each site operates under a “common platform,” giving us the ability and flexibility to quickly react to our customer's changes in demands. We deliver operational excellence, innovation, and rapid commercialization to the world’s leading personal care, home, food and beverage brands.

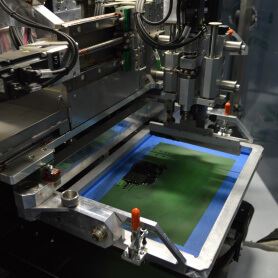

Enhancing Product Appeal Axium Packaging’s versatile decorative techniques, ranging from laser etching and silk screening to hot stamping and shrink labeling, offer our customers many ways to increase product appeal at the point of purchase. Our state-of-the-art technology and innovative design teams work with you to create high-quality, high-impact graphics with quality, precision, and clarity.

Silk Screening

- 6 pass linear silk screening machine

- Servo (3D CAD) driven rotary silk screening

- 360-degree print technology

- Expansion and review of digital printing heads

Pressure Sensitive Labeling

- Front/Back standard labeling

- 360 wrap labeling (round & oval packaging 3D cad driven)

Shrink Sleeve Labeling

- Flexible machine for lower MOQs

- Large-scale machine to allow continuous large runs

Spray Coating

- High-end prestige coating of plastic and bottles and jars

Hot Stamping

- Glass and Plastic options with a broad range of color options.

High-End Mold Embossing/Debossing

- High-precision CNC technology

- Electric discharge machining capabilities