If this is your company, CONTACT US to activate Packbase™ software to build your portal.

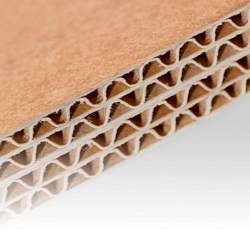

Corrugated board was already an innovation when it first appeared on the market. BillerudKorsnäs now offers an evolution of the material: the world’s strongest and most reliable fluting.

Over the years, one of the biggest challenges in the packaging industry has been to optimize the amount of paper used per box, yet increase the level of protection of the product. BillerudKorsnäs has managed to do just that. By constantly challenging themselves, they have made a strong product even stronger, achieving more with less.

Today, BillerudKorsnäs manufactures the world’s strongest and most efficient fluting, using less material for increased protection. This development helps reduce transport costs and minimizes losses in the supply chain. In other words, lighter and stronger packaging with less waste. An evolution of both material and packaging solutions.

The single most important end use for corrugated is transport packaging for a wide range of products. Thanks to continuous construction improvements, delicate items like fruit and vegetables can be transported with minimal damage.

Corrugated board is also used to package and protect heavy and expensive products like tools, electronic equipment and spare parts in the automotive industry.

Today, corrugated board often replaces styrofoam or similar plastic-based materials used for shock absorption, a sustainable and eco-friendly solution.

Corrugated board has even started to replace styrofoam and plastic filling in the packing and transport of fragile objects. Using a renewable, recyclable, and biodegradable material, the packaging can be recycled and easily used again and again.