If this is your company, CONTACT US to activate Packbase™ software to build your portal.

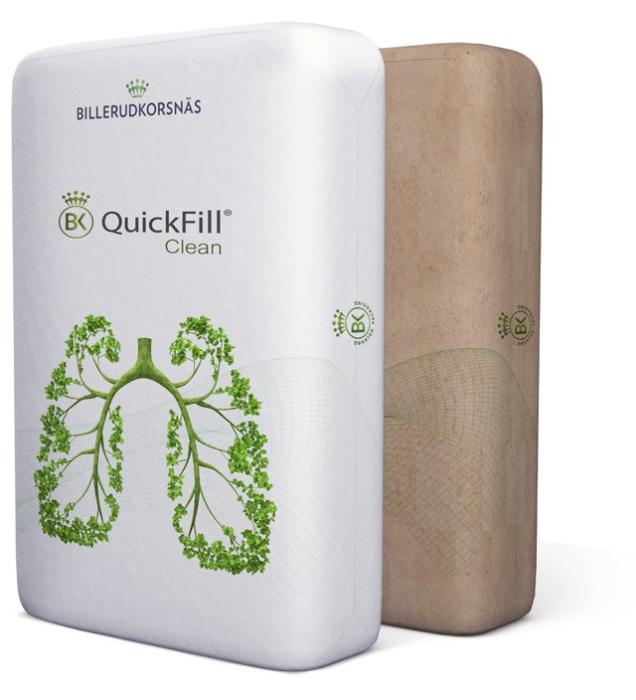

QuickFill Clean is the latest innovation in the cement industry allowing cement manufacturers that use woven polypropylene (WPP) sacks to immediately increase profit by converting to a plastic-free solution that's cleaner for the environment and cleaner during manufacturing and transport.

Breathing naturally in dusty working environments day in, day out is tough!

During filling and distribution processes, conventional cement sacks using woven polypropylene plastic (WPP) lose up to five per cent of their cement powder, a level of waste that affects employees, the environment, and the profitability of a business.

The QuickFill Clean sack solution from BillerudKorsnäs is a healthier alternative for both business and the planet

Cement sacks take time to fill and high volume means that every second counts. With superior deaeration, QuickFill Clean sacks swap air for cement powder in record time bringing a noticeable improvement in productivity.

The sacks are tight and strong enough to move towards zero waste. Strong primary fibres and the latest sack paper technology ensure cement loss is kept to an absolute minimum.

QuickFill Clean sacks are a perfect alternative to plastic (WPP) sacks. Not only do they come from sustainable sources but they also prevent litter. QuickFill Clean sacks keep cement where it belongs, in the sack so that cement dust doesn't escape during filling and transport. The result is a cleaner, healthier working environment which is better for business and for customers.