If this is your company, CONTACT US to activate Packbase™ software to build your portal.

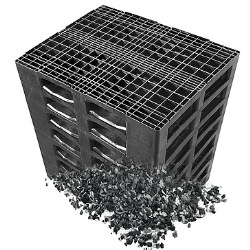

The rugged BPP i9 pool pallet from Cabka-IPS.

The beverage industry places particularly high demands on pallets, especially when they are used as pool pallets. They must be extremely rugged, solidly built and long-lasting. At the same time they must be light and easy to handle.

To meet these requirements, Cabka-IPS has developed the BPP i9 beverage pool pallet. Made of recycled HDPE, it weighs only 23 kg, about half as much as a comparable wooden pallet. This makes handling easier and reduces CO2 emissions in transport. The BPP i9 is manufactured with gas-assist low pressure injection technology. In this process, hollow channels are generated within the pallet, making it both lighter and more rigid.

The BPP i9 has a high load capacity of 1,500 kg. Its rugged design ensures a long service life in pooling. Repairs are hardly ever necessary. Moreover, it never has contamination from splinters or woodchips, which is a problem with wooden pallets.

The BPP i9’s anti-slip strips and grommets ensure firm and safe handling of beverage containers. Extra wide openings between blocks make the pallets particularly easy to handle and protect them from damage. The BPP i9 was developed for the Dutch Dranken Pallet Beheer (DPB) pallet pool, which is already successfully putting 400,000 of them to use. They are manufactured according to the “Cradle to Cradle” principle in which the pallet is recycled at the end of its life cycle and the material reused.