If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Carbios announces a major milestone in the optimization of its biorecycling process of post-consumer PET plastic bottles, making it possible to strengthen its economic competitiveness and accelerate its scaling up towards the industrial demonstration stage.

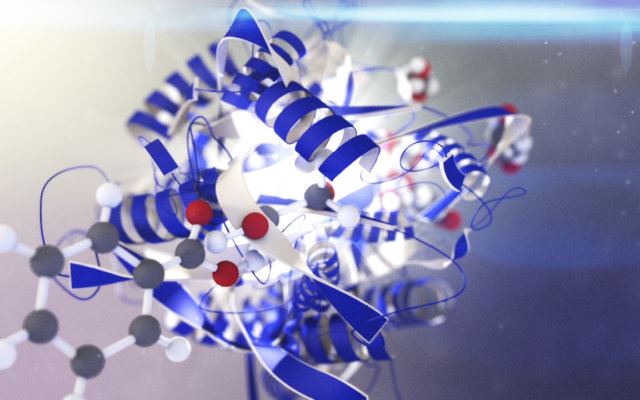

Previously, Carbios announced that it had discovered a particularly well-suited enzyme to degrade PET plastics into their original monomers: PTA (terephthalic acid) and MEG (mono ethylene glycol).

Following these results, work has been undertaken to optimize the enzyme used in Carbios’ biorecycling process, with the support of the teams from Toulouse White Biotechnology (TWB), and in particular the Engineering Laboratory of Biological Systems and Processes (LISBP).

A molecular modelling study has been carried out to analyze the relations between the 3D structure of the enzyme and its efficiency. This has made it possible to set targets enabling to improve performance and achieve a conversion rate that only Carbios can claim today.

Thus, the time of hydrolysis has been divided by three, 97% conversion being obtained after 24 hours of reaction. Such a result enables to optimize the profitability of the process and significantly increase the flows of PET waste that can be treated enzymatically.

Alain MARTY, Scientific Director of Carbios commented: “Today, we are the first in the world to achieve such a high level of performance in the biological recycling of PET plastics. Our work represents a major move forward that will enable the entire plastics industry to engage in a responsible transition towards circular economy."

Jean-Claude LUMARET, CEO of Carbios adds: “This is undoubtedly a key step that reinforces the economic potential of our biorecycling process which is applicable to all PET plastics, whether they are coloured, opaque or complex. We are already working with TechnipFMC and other leading industrial and academic partners to lead this year’s pilot stage of our technology.

Given our progress, we decided to accelerate these developments and initiate the industrial demonstration stage in 2019 with the set-up of a 10,000 metric tons plant that will produce the first volumes of virgin PET from our technology by mid-2021.“