If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The AM 400 horizontal cartoning machine automatically forms and closes boxes using pre-glued cartons. It essentially consists of a carton magazine, a box conveyor equipped with a folding system and a device for opening and closing the flaps. Product insertion in the cartons is carried out by hand. Most components of the machine are adjustable so that format changes are particularly easy to carry out.

Description

- Mechanical and pneumatic operation

- Painted steel construction,

- Adjustable bucket conveyor

- Carton magazine equipped with compacting device

- Alarm for detection of low level of cases in the magazine

- Alarm for boxes not open

- Box pick-up through sucker arm with Venturi system

- Mobile device for flap opening to ease product introduction

- Hot-melt glue closing

- Handwheel and reference ruler for format change

- All parts in contact with the product are made of AISI 304 stainless steel

- Safety guards (electrowelded wire mesh) on all parts complying with CE normative

- Machine with CE marking

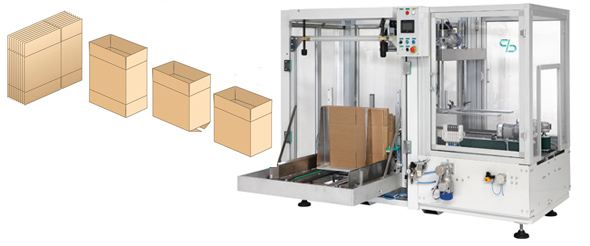

Automation conceived for box forming through the closing of the four lower (bottom's) laps so that the boxes are ready for vertical filling either in manual or automatic mode.

The forming device consists of a structure made of metallic tubes and painted panels with adjustable bases and supporting unit.

Lower lap closing is done with adhesive tape or glue. The carton magazine has been built with an inclined position to ease the operator. With a capacity of about 100 cartons, it is equipped with an automatic feeding system to always assure the carton presence at the collection point. Adjustments for format change are carried out by means of handwheels. Cartons are opened by means of a pick-up head with suckers operated by a vacuum pump. Lap closing is done pneumatically. All the pneumatic material the machine is equipped with complies with ISO rules whereas its electric control board complies with CE norms.

Description:

- Painted steel construction

- Electro-pneumatic functioning

- Size-change adjustments through handwheels

- PLC-controlled electric installation

- Lower lap closure through either 50mm high adhesive tape or glue

- Carton pick-up through sucker arm with Venturi system

- Carton magazine equipped with compacting device

- Safety guards (electrowelded wire mesh) on all parts complying with CE normative

- Machine with CE marking

Automation for cases forming through the closing of the four lower laps so that the cases are ready for vertical filling by means of an incorporated Pick & Place device.

The forming device consists of a structure made of metallic tubes and painted panels with adjustable bases and supporting unit.

Lower lap closing is done with adhesive tape or glue. The carton magazine is in horizontal position; it has a capacity of about 100 cartons and it is equipped with an automatic feeding system to always assure the carton presence at the collection point. Adjustments for format change are carried out by means of handwheels. Cartons are opened by means of a pick-up head with suckers operated by a vacuum pump. Lap closing is done pneumatically. All the pneumatic material the machine is equipped with, complies with ISO rules whereas its electric control board complies with EC norms.

The product arrives from the packaging machine through a feeding conveyor-belt which subjects it to a dimensional control. Another conveyor separates the products to make the correct quantity be fed to form a layer. Product feeding is also managed by a compacting cylinder and a by-pass unit to allow manual operations.

The carton to be filled comes from the forming device on which some adjustable pneumatic stops and some photoelectric cells are mounted for carton presence detection and control.

A centring funnel, with vertical movement, and fitted to ease the filling process, enters into the carton. The two-axle manipulator, driven by electric motors and controlled by PLC, collects the layers previously prepared to transfer them inside the carton and up to the preset deposit level. The product is collected by means of vacuum suckers or, alternatively, pneumatic pliers.

All the pneumatic components the machine is supplied with comply with ISO norms and the electric control board complies with EC norms.

Description of the carton packer:

- Painted steel construction

- Electro-pneumatic functioning

- Size-change adjustments through handwheels

- PLC-controlled electric installation

- Lower lap closure through either 50mm high adhesive tape or glue

- Carton magazine with pick-up sucker arm

- Safety guards all around complying with the rules in force

- Machine with CE marking

Pick & Place description:

- Product conveyor-belt with variable speed controlled by inverter, and stop function to separate the product

- Pneumatic compacting device

- By-pass device for product unloading

- Centring funnel

- Pick-up head with vacuum or pneumatic pliers

- Pick & Place's movements controlled by an integrated PLC with controls and gearmotors

The horizontal cartoning machine model AS 220 automatically forms and closes boxes using pre-glued cartons. It essentially consists of an infeed conveyor with intermittent motion for product insertion, a carton magazine, and a second conveyor equipped with a device for inserting, folding and closing the box flaps. Product insertion on the conveyor can be either manual -carried out by an operator -, or automatic by means of a synchronizing device. Most of the groups the machine is made up with are adjustable, therefore on the occasion of a format change the operator does not need to replace all of them.

Description

- Mechanical and pneumatic operation

- Painted steel construction

- Adjustable bucket conveyor

- Infeed conveyor with adjustable pushers

- Carton magazine equipped with compacting device

- Alarm for detection of low level of cases in the magazine

- Alarm for boxes not open

- Box pick-up through sucker arm with Venturi system

- Arm for product insertion in the boxes equipped with safety system

- Mobile device for flap opening to ease product introduction

- No product-no carton feature

- Hot-melt glue closing or hook closing

- Handwheel and reference ruler for format change

- All parts in contact with the product are made of AISI 304 stainless steel

- Safety guards (electrowelded wire mesh) on all parts complying with CE normative

- Machine with CE marking

This machine forms the cases and opens them so that they can be horizontally filled and their flaps automatically closed. The cases are manually placed in inclined and motorized magazine for a correct positioning of the case in the pick up place. A suction cup head pick up the case and place it a chain. Electro-pneumatic devices grant with total safe and guarantee a perfect formation of the case. During the forming there is the filling operation and the closing of the flaps.

The insertion of the product is automatic, through a mechanical arm with precision movement and check of the product to insert.

The transport of the case is made by devices fitted on lower and upper chain, that allow to keep the perfect form. The closing of the flaps can be made by adhesive tape, hot melt or both systems.

Description:

- Electropneumatic operation

- Painted steel construction

- Handwheel adjustment during format change

- Cartons pick-up through sucker arm with Venturi system

- Cartons' magazine with compacting device

- PLC controlled electrical system

- Flap sealing with tape or hot-melt glue

- Touch panel for job receipt

- Safety guards all around complying with CE rules

- Machine with CE marking

The CA300 is a carton closing machine which automatically folds the flaps and closes the lid of a box.

Flaps are folded whereas lid is closed through hot-melt gluing technique (which consists in spraying the glue on some required points through a gun). Format change is easily carried out by means of some adjustable handwheels.

Characteristics

- Mechanical and pneumatic operation

- Painted steel construction

- Variable speed controlled by inverter

- Electric system controlled by a PLC

- Box conveying through intermittent movement

- Safety guards complying with CE rules

- Machine with CE marking

The CL 300 is a carton closing machine which automatically folds the flaps and closes the 3-flap lid of boxes. The three flaps of each lid are closed through hot-melt gluing technique (which consists in spraying the glue on some required points through a gun). Format change is easily carried out by means of some adjustable handwheels.

Description:

- Mechanical and pneumatic operation

- Painted steel construction

- Variable speed controlled by inverter

- Electric system controlled by a PLC

- Box conveying through intermittent movement

- Pneumatic flap closing system

- Lid closing device through hot-melt glue applicator

- Safety guards complying with CE rules

- Machine with CE marking

The carton former FS400 is a machine which automatically sets up folded cartons and puts together boxes with or without cover. It consists of a carton magazine unit equipped with an automatic arm which lifts cartons from the magazine by means of suckers and of a hot glue spraying device for gluing flaps. Once the carton is formed by means of a mould it is transported along a conveyor. Format change can be easily done by just regulating the special hand-wheels. The forming unit - consisting of one single part - has been constructed in order to avoid regulating operations.

Characteristics

- Mechanical and pneumatic operation

- Painted steel construction

- Carton magazine whit automatic arm equipped with suckers with Venturi's system

- Box assembling through hot-melt glue application or hook closing system

- Former's mould with electrical axis

- Female mould adjustable through handwheels (applicable to all the formats)

- Electric installation system controlled by a PLC

- Safety guards complying with CE rules

- Machine withCE marking