If this is your company, CONTACT US to activate Packbase™ software to build your portal.

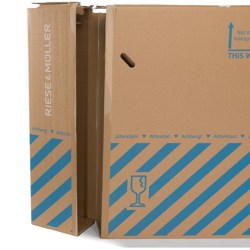

Riese & Müller make exceptional e-bikes and need quality packaging to get their products safely and securely to market. Below is a condensed version of a recent article in VerpackungsRundschau about how DS Smith looked at their entire supply cycle to develop an entirely new packaging that’s better for protection, and better for customers.

Challenge

Replace Riese & Müller’s packaging which took too long to pack, used metal clamps which caused too much noise in the factory, included some non-recyclable materials and needed knives to be opened which could lead to injuries or damage to the bicycle.

Our Approach

We started by looking at the entire supply cycle in which the packaging has to operate and systematically developed improvements at each and every stage so that Riese & Müller had packaging that was every bit as innovative, high-quality and effective as their own bicycles.

Result

- Reduced cost and complexity in packaging

- Reduced packing time

- Increased protection of premium product

- New packing process means happier employees

- Reduced possibility of injury at unpacking

- Packaging and brand attributes are better aligned

DS Smith takes pride in collaborating with its customers to fully understand their processes, needs and the individual requirements of their products. Only then can we deliver these outstanding results and generate real value for the customer with cost and process-optimised transportation packaging.