If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Unique properties, endless possibilities

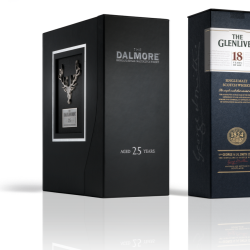

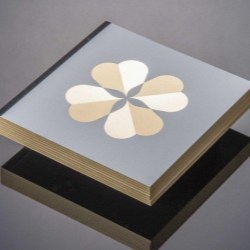

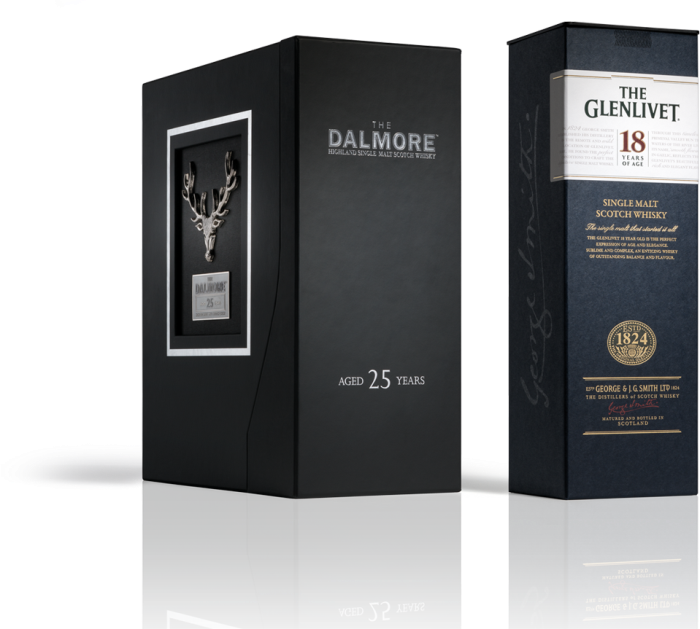

Eska®black is used in products with one or two black sides and products showing the inner black board at the cutting edge. It is therefore perfectly suited for use in luxury packaging for beauty products and cosmetics, high-end electronics, jewellery and watches, textiles and clothing, and wine and spirits. Eska black is made with recycled material; luxury and sustainability now go hand in hand.

The Anatomy of Luxury

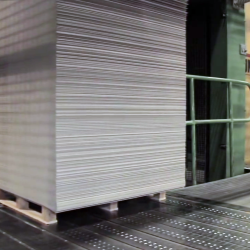

Eska black is a three-layer board consisting of an inner layer made from 100% recycled fibres with deep black and glossed liners on both sides. Together, these three layers contain at least 70% recycled fibres.

The new product is available in calipers from 1.25 – 1.75 mm

Eska black can be used in different ways to enhance the luxury image of a brand

This makes Eska black perfect for premium rigid boxes and interiors, as it will show the luxury products inside to full advantage. Eska’s experts can give you advice on all the possibilities Eska black offers.

Eska & sustainability

All Eska products are made with post-consumer paper and board and are FSC® Mix and PEFC Recycled certified. Eska Graphic Board has a low water consumption per tonne of board produced. We also use a low amount of energy per tonne of board and operate highly efficient equipment for steam and electricity production, minimising the impact on the environment. Eska Graphic Board is ISO 9001/14001/50001 certified.

Eska Graphic Board strives to achieve zero waste company status for its production facilities

Improving energy consumption profile

Eska is one of the world’s leading companies in energy and environmental management in paper and board production. Over the years, Eska has always invested a lot in measures and facilities aimed at improving its energy consumption profile.

In the second half of 2016 Eska will start operating a gasification plant, which will convert the rejects from the recycled paper into gas and use this to generate steam for its board-processing machinery. By converting the rejects into steam on-site, the mill in Hoogezand will consume considerably less natural gas in its production process every year, and minimise the amount of waste generated by its mills.

Process and water management

In one of its mills, Eska has a closed water system. As a result, it has a low water usage per tonne of board produced. It also has a very good score for discharged water volume and emissions in water.