Public

Essentra Packaging Catalog

Essentra Packaging Documents

Essentra Packaging Gallery

Essentra Packaging Locations

Essentra Packaging News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Essentra manufactures cartons for a variety of industries, incorporating a wide range of styles, designs and print finishes. From cardboard to plastic, we print on a huge variety of materials to create innovative, practical and stand-out packaging for your products. We develop, design and make structural prototypes in-house to ensure a seamless, rapid service – even for short-run orders.

Solutions include intricate die cutting and blanking, offset printing with both UV and conventional inks, offline proofing facilities, computer-to-plate and processing technologies, specialist gluing solutions, printing on both sides of board, window-patched and wrap-around windows and specialist barrier packaging where a long shelf life is required.

CARTON CAPABILITIES

- Designs and prototypes developed in-house

- Computer-to-plate and processing technologies

- Specialist gluing solutions - side seam, crash lock, four corner, flat (unglued)

- Conventional and metallised board with double-side printing

- Carton and label/leaflet combination

- Micro-perforations

- 6-colour press printing, possible on cartons with a thickness of 0.08mm–1.1mm

- Ability to service short runs

- Supply of specialist packaging and filling machines, either new or refurbished

- Offset print process with both UV and conventional inks; UV and water-based coatings are also available

FEATURES AND OPTIONS

- Window-patched and wrap-around windows registered to creases

- Varnish finishes including matt, gloss, pearl, satin, soft touch, reticulated and blister

- Hot / cold foiling and foil blocking

- Cartons with braille

- Embossing and debossing

- Specialist barrier packaging where a long shelf life is necessary

- Ability to print, glue and block on plastic substrate

- Boxes, sleeves, 5th panel, straight and reverse tuck

- Die cutting and blanking in different sizes

ADDITIONAL SECURITY FEATURES

- Anti-counterfeiting and authentication technology

- Anti-theft labelling

We supply a range of self-adhesive labels on a roll for automated high-speed application. Our technical expertise in labels ensures the right adhesive is selected for permanence, repositionability and tamper evidence, while our Label Vision Systems check for label print accuracy.

Strict quality systems ensure 100% control from origination to final production. We can also provide a total label reconciliation service, removing the need to count labels for specific lines or returning stock.

AVAILABLE SUBSTRATES

- Pressure-sensitive papers and films

- Flexible packaging

- PVC plastics

- PLA and recycled labels

SPECIALIST FINISHING CAPABILITIES

- Laminations

- Hot or cold foil stamping

- In-line rotary embossing

- Form / label combinations

- Up to 10-colour capability

- Ability to deliver in roll, fan-fold and sheet formats

- Digitally printed label options

ADDITIONAL SECURITY FEATURES

- Tamper-evident labels

- Hidden hologram labels

- Pearlescent and thermochromic inks

- Foils, holograms and tactile effects

- Braille printing

- Security slitting

- Over-lamination

- Sequential numbering

- Unsupported

- Self-adhesive

Our leaflets come in a range of sizes and different formats: folded, flat and on-roll. Leaflets are printed on both reel and flat sheet offset litho presses for pack insertion on high-speed lines. We employ state-of-the-art inspection, defect detection and tracing equipment to ensure consistent quality and text matching to customers’ requirements. We have a range of machinery sizes so we can produce larger leaflets to accommodate changing legislative demands and multiple languages.

REEL FORMAT OPTIONS

- Simple reel

- Double, triple and quadruple pre-folded leaflets (PFL) – ideal for very high-speed carton lines with in-house leaflet folding

LEAFLET FORMAT OPTIONS

- Flat leaflets

- Parallel / cross folded

- Single- and double-folded booklets

- Multiple part sets

- Mini books and cards

- Glued outsert- or tagsert-folded leaflets

- Multi-unit, multipage leaflet combinations

In addition to secondary packaging, we also provide printed primary packaging capability, which includes features such as child resistance and multicolour print to fulfil the blister pack needs of our customers.

In our state-of-the-art class 100,000 standard clean room, we can print on a range of different materials and thicknesses to meet individual customer specifications.

PRODUCTS AND CAPABILITIES

- 20-micron hard foil

- 25- / 30-micron soft foil

- Childproof foil lids

- Laminate lids

- Printed Cold Form (PA / Alu / PVC) substrate

- Medical paper (for component blistering such as disposable syringes or medical components requiring ETO sterilisation)

- Laminate materials for sachet packaging of granulate and powder products

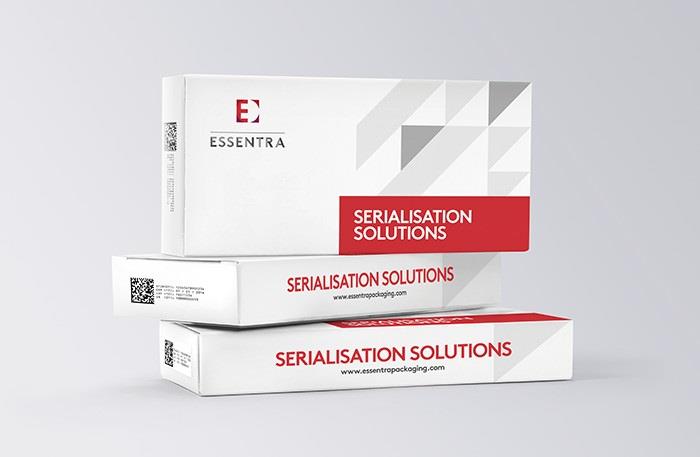

Counterfeiters are getting smarter and more sophisticated, finding more intelligent ways to infiltrate the supply chain. To address this growing threat, various anti-counterfeiting measures are being implemented around the globe, including serialisation. Serialisation is the system of tracking, tracing and verifying products via unique identification codes.

Essentra understands the challenges and increased threats posed by counterfeiting and have designed a range of serialised carton and label solutions designed to maximise security and traceability of your products.

Essentra digitally prints unique item-level serialisation from externally supplied data, negating the need for customers to set up and manage print in-house. Quality control ensures the correct and appropriate data management system serialisations are printed without duplication, with post-print checks to confirm readability. Used serialisations are recorded and a report provided to satisfy the downstream data management requirement of our customers.

OUR SOLUTIONS INCLUDE

- Serialised cartons

- Serialised labels

- Overt and covert authentication technology available

- Minimises impact of serialisation on packing lines

Essentra digitally prints unique item-level serialisation from externally supplied data, negating the need for customers to set up and manage print in-house.

Quality control ensures the correct and appropriate data management system serialisations are printed without duplication, with post-print checks to confirm readability. Used serialisations are recorded and a report provided to satisfy the downstream data management requirement of our customers.

Tamper verification can be added by sealing carton access points either via glue or using a label such as fibre tear, void release or frangible.

FEATURES AND BENEFITS

- Overt and covert authentication technology available

- Minimises impact of serialisation on packing lines

.jpg)

.jpg)

.jpg)