FH Packaging Links

FH Packaging Blog Posts

3 Industries Where Polystyrene Products are Useful

3 Reasons Why Airless Pump Bottles are Better Than Closures

5 Best Jars and Glass Bottles for Beard Oil Products

5 Great Benefits of Glass Jar Packaging

Disposable Face Masks and Plastic Container Packaging

Glass Bottles and Droppers with Your Small Business

Hand Sanitizer Bottles and Alternative Packaging

How Many Drops Are in Essential Oils Bottles?

How to Choose Between Glass and Plastic Jars

Specialized Skincare Packaging Ideas and Design Guide

The Type of Bottle Closures

The Types of Droppers and Graduated Pipettes

The Types of Droppers and Graduated Pipettes

The Ultimate Guide to Graduated Droppers

Tips for Organizing a Vitamin Storage System

Top 5 Skincare Packaging Ideas You Should Consider

Which Lids Go Great with Your Plastic Jars

Which Liner Should I Choose for My Caps?

Why You Should Use A Euro Dropper Bottle for Storing Essential Oils

Your Complete Guide to Child Resistant Closures

FH Packaging Company Announcements

Public

FH Packaging Blog/Forum

FH Packaging Catalog

FH Packaging Links

FH Packaging Locations

The Type of Bottle Closures

The Types of Droppers and Graduated Pipettes

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Which Liner Should I Choose for My Caps?

For a new customer, this question is the most important you would want to ask yourself when purchasing a new cap with a liner. There are many factors to take into question when choosing a Liner for your specific product. Below are some of the main products that are used with the specified liner. Please note that these are general recommendations and not mandatory to use with your product. If you have questions, please contact us by email, phone, or live chat and one of our customer care specialists will be glad to help with any inquire you might have. We also always recommend choosing a sample first before making a big purchase.

- HS035 – Heat Induction: Liners that bond to the land of the bottle using special equipment. Common for food, sauce, and other products requiring a seal for consumer confidence

- PS22 – Pressure Sensitive: Liners that bond to the land of the bottle when the cap is removed. Common for dry products, pharmaceuticals, vitamins, and supplements

- Polyethylene: Common with Concentrated Coffee, Beverages, Juice, Dry Health Foods, Honey, Syrup, etc.

Heat Induction Seal Liner (HIS Liner)

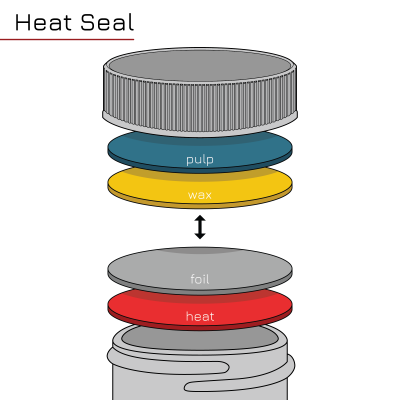

[caption id="attachment_33149" align="alignnone" width="400"] Types of Seals: Heat Seal Liner Infographic[/caption] Our black plastic screw top cap features a heat-sealed aluminum liner to ensure customers that their product has not been tampered with. When installed properly, the cap’s heat induction seal forms an airtight inner seal that protects contents against oxygen and moisture and provides a tamper-evident-proof safety. The liner is an aluminum foil-coated liner that has paper on one side and foam on the other. It features a heat sealable coating that is laminated to polystyrene foam. These types of heat induction seals can be used with Polyethylene, PET, PP, and PVC. In addition, our black plastic screw top cap is great for a variety of uses for cosmetics and personal care products and is easy to use. The heat seal liner preserves the product for a longer period of time by trapping in oxygen to increase the longevity of products such as lotion, soaps, sanitizers, and more. *Heat Induction Seals (HIS) are not suitable for products containing oil

Types of Seals: Heat Seal Liner Infographic[/caption] Our black plastic screw top cap features a heat-sealed aluminum liner to ensure customers that their product has not been tampered with. When installed properly, the cap’s heat induction seal forms an airtight inner seal that protects contents against oxygen and moisture and provides a tamper-evident-proof safety. The liner is an aluminum foil-coated liner that has paper on one side and foam on the other. It features a heat sealable coating that is laminated to polystyrene foam. These types of heat induction seals can be used with Polyethylene, PET, PP, and PVC. In addition, our black plastic screw top cap is great for a variety of uses for cosmetics and personal care products and is easy to use. The heat seal liner preserves the product for a longer period of time by trapping in oxygen to increase the longevity of products such as lotion, soaps, sanitizers, and more. *Heat Induction Seals (HIS) are not suitable for products containing oil

Pressure Sensitive Liners

[caption id="attachment_33151" align="alignnone" width="400"] Types of Seals: Pressure Seal Liner Infographic PS22[/caption] This black plastic screw top cap includes a PS liner inside the cap. In other words, A pressure-sensitive liner is a variety of polystyrene liners. For instance, it is commonly referred to as poly liners. An ideal general-purpose liner material, the compressible Pressure Sensitive foam creates a stable seal. In addition, Pressure-sensitive liners are odor resistant and pulp dust-free. Pressure-sensitive liners are recommended to be used with powders or dry products. Pressure-sensitive liners are not recommended for use with liquid. Pressure Sensitive liner has an adhesive coated on foam seal and a release coating on the back that does not come in contact with the product. It adheres to either glass, metal, or plastic containers when applied and sticks to the container when the cap is removed. Once the cap is applied, it should not be removed for at least 24 hours to ensure proper adhesion. Pressure-sensitive liners have a recommended shelf life of 6-months.

Types of Seals: Pressure Seal Liner Infographic PS22[/caption] This black plastic screw top cap includes a PS liner inside the cap. In other words, A pressure-sensitive liner is a variety of polystyrene liners. For instance, it is commonly referred to as poly liners. An ideal general-purpose liner material, the compressible Pressure Sensitive foam creates a stable seal. In addition, Pressure-sensitive liners are odor resistant and pulp dust-free. Pressure-sensitive liners are recommended to be used with powders or dry products. Pressure-sensitive liners are not recommended for use with liquid. Pressure Sensitive liner has an adhesive coated on foam seal and a release coating on the back that does not come in contact with the product. It adheres to either glass, metal, or plastic containers when applied and sticks to the container when the cap is removed. Once the cap is applied, it should not be removed for at least 24 hours to ensure proper adhesion. Pressure-sensitive liners have a recommended shelf life of 6-months.

Polyethylene Foam Liner

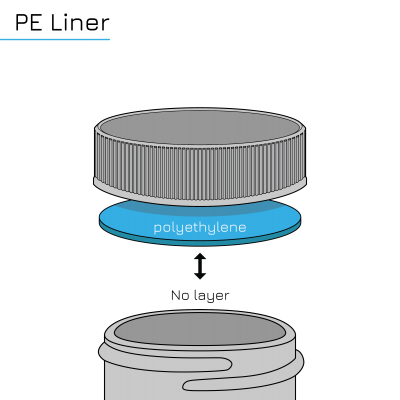

[caption id="attachment_33150" align="alignnone" width="400"] Types of Seals: PE Polyethylene Foam Liner Infographic[/caption] This lid includes a PE foam liner inside the cap. In other words, A PE liner is a variety of polyethylene foam liners. For instance, it is commonly referred to as poly liners. It is a flexible plastic liner specifically designed to line the inside of a glass, metal, or plastic container. An ideal general-purpose liner material, the compressible PE foam creates a stable seal. In addition, PE liners are odor-resistant and pulp dust-free. They also have good chemical resistance to acids, alkalis, solvents, alcohols, oils, household cosmetics, and aqueous products. PE liners are not recommended for use with hydrocarbon solvents.

Types of Seals: PE Polyethylene Foam Liner Infographic[/caption] This lid includes a PE foam liner inside the cap. In other words, A PE liner is a variety of polyethylene foam liners. For instance, it is commonly referred to as poly liners. It is a flexible plastic liner specifically designed to line the inside of a glass, metal, or plastic container. An ideal general-purpose liner material, the compressible PE foam creates a stable seal. In addition, PE liners are odor-resistant and pulp dust-free. They also have good chemical resistance to acids, alkalis, solvents, alcohols, oils, household cosmetics, and aqueous products. PE liners are not recommended for use with hydrocarbon solvents.

FH Packaging Lids & Liners

[ux_stack] [ux_products cat="276"] [/ux_stack]