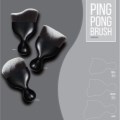

FS Korea, known to many as one of the region's leaders with regard to the design, development, and deployment of innovative cosmetic and personal care packaging, has recently upgraded its production facilities. The company has set up an ancillary packaging factory that produces key elements to be used with a variety of its core packaging products. The new facilities will produce mostly sponges and brushes, along with the capability to decorate the items created.

The new facilities offer increased output, ensuring that sponges can be cranked out to the tune of around 300,000 a week. Applicators, including brushes and stemmed sponges go even further, up to over half a million per week.

Currently, the factory allows the company to produce ancillary products in a number of materials including nitrile rubber (NBR), styrene-butadiene rubber (SBR), ethylene propylene diene monome rubber (EDPM), cotton puffs, cellulose, and more.

Concerns about safety are more than addressed by FS Korea's factory using only toxic-free sponges (which are also latex-free), and ensure that production is always done with toxin-neutralizing agents.

.jpg)

.jpg)

.jpg)

.jpg)