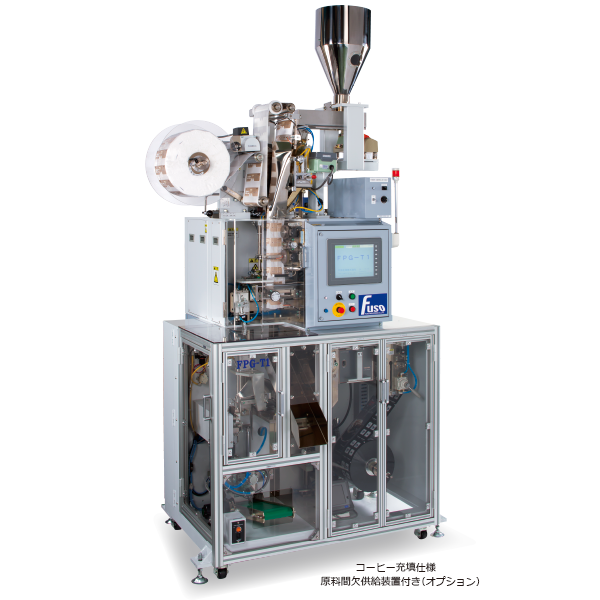

World No.1 market share

drip coffee packaging machine.

● a variety of drip coffee multi performance from the bag to the individual packaging of the tag thread with flat bag

● gas filling is basic, diverse up in the optional equipment productivity to the maximum

● up to 50 / min capacity

![]()

| Interior packaging unit | Package presentation | Ultrasonic three-way seal |

| Use packaging materials | Nylon gauze, non-woven fabric, ultrasonic sealable packaging material | |

| Weighing system | Slide trout weighing | |

| Packaging and filling amount (selectable) | 10~49cc (when 23mm mass use) 10~35Cc (16Mm mass is used) |

|

| Bag size (longitudinal feed length) | 40~80mm (the case of the only interior 100mm) | |

| Longitudinal feed size change method | Set in 1mm units in the above dimensions | |

| Bag dimension (width method) | 60~90mm | |

| Width direction size change method | Shoot exchange | |

| Exterior packaging unit | Package presentation | Heat sealing three-way seal |

| Use packaging materials | Heat-sealable exterior film | |

| Bag size (longitudinal feed length) | 85~125mm (will be the interior dimension + 30~35mm more) | |

| Longitudinal feed size change method | Change in the adjustment screw of the crank portion | |

| Bag dimension (width direction) | 70~110mm (will be the interior dimension + 30~35mm more) | |

| Width direction size change method | Sailor exchange | |

| Packaging capacity | 30 to 50 bags / min | |

| Machine Size | 1200 (W) × 1090 (D) × 2510 (H) mm | |

| Machine weight | About 880kg | |

| Use power | This body: three-phase 200V 2.2kw equivalent compressor: 3.7kw equivalent about 320L / min air dryer: 3.7kw for equivalent |

|

option

● coffee filling specification (VFR specifications, such as conic specification)

● interior gas input device

● hopper stirring device

● sub hopper pecking equipment

● raw materials shot swatter equipment

● slide mass vibrator

● printer (hot printer or thermal printer)

● weighing machine 100SA-FW (N3)

● raw materials intermittent supply device (for coffee filling)