GEKA is committed to measuring its global environmental footprint. Maxime Darimont, Sustainability Manager and Frederic Duquet, Head of Global R&D and Innovation offer further insight.

MAXIME DARIMONT SUSTAINABILITY MANAGER APS DIVISION has thirteen years of experience in environmental, health, safety and sustainability in several countries and organizations (Belgium, France, Poland) before joining Sulzer in 2017.

FREDERIC DUQUETHEAD OF GLOBAL R&D AND INNOVATION AT GEKA has twenty years of experience in R&D and product development in the cosmetic packaging sector, before joining GEKA-Sulzer in December 2019.

Sustainability covers a wide range of topics. How is this implemented at GEKA?

MD: Sustainability is a broad concept based on the triple-bottom-line: of planet, people and profit. Put simply, it refers to the ability of human civilization to coexist harmoniously alongside the biosphere. As a company it means it refers to its ability of being resilient in a changing world and set a direction to achieve the above explanation. At Sulzer level, the other business create products which are capable to perform at a very high energy efficient level (Pumps Equipment) but also to avoid the creation of new machinery by retrofitting them (Rotating Equipment Services). In order to limit global warming to + 1.5° C, global CO2 emissions have to be reduced annually by 5-6%.

GEKA has decided to act on data-based measures. We are strongly connected to a carbon-based economy, from the raw materials that mostly come from fossil fuels to the delivery of goods to the customer. We calculate our own value chains carbon footprint in connection with the Green-house Gases protocol. This will allow us to take data-based action to continue doing business with alternative resource consumption.

To achieve this, a training framework is being developed to get all employees on board and to ensure that everyone understands the challenge and how they can contribute to the challenge. A clear management focus is also set to continue this change within GEKA.

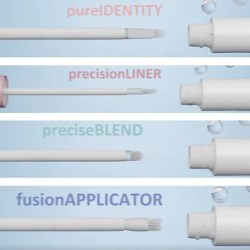

FD: Sustainability is part of our core values at GEKA. In the R&D department, we have developed initiatives to work at different stages.

There are reflections at the innovation level regarding refillable and reusable packaging, while our technology department is working the process adaptation to homologate new sustainable materials. Of course, this approach will be integrated in all new product developments by the engineering department. As a packaging supplier for the cosmetics industry, the decisions that we make during product development are important. In practice, the following different approaches can be combined:

- Weight reduction to reduce material consumption without affecting the functionality of the packaging

When it comes to packaging sustainability, it is important to think about responsible resource management. It is essential to reduce the amount of material used right from the start. Never-extracted raw materials, saved energy or water and lower transport requirements are the results of improved material consumption.

- Increasing use of recycled plastic feedstocks

In the near future, the use of PCR will be defined as the standard for plastic packaging. The goal is to integrate up to 100% of the PCR (Post Consumer Resin) into our components. We can already offer the use of PCR material for most caps and bottles.

- Investigating the use of bioplastic packaging

Bioplastics offer great potential for the future, but they are considered more of a medium-term solution since they often require changes to the product design and the associated production tools. Still, we have some concrete application solutions in stock. Being part of the SulzerGroup is a great advantage here, as ChemTech have built up expertise and a network of suppliers in the bio-ba-sed plastics industry. We will use this know-how for our specific business requirements.

What are the main challenges facing the cosmetic packaging industry?

FD: The packaging industry faces growing consumer and regulatory pressure to find sustainable packaging options that ‘reduce, reuse and recycle’. The production of sustainable packaging is not a short-term trend, as increasingly more consumers are demanding reasonable, sustainable packaging from their cosmetic suppliers. PCR will play an increasingly important role.

However, capacity limitations in PCR material lead to PCR usage being a "phase-in" process and not an immediate or sudden transition. Evaluated and tested biomaterials remain medium-term solutions, as they often require changes to the product concept and the associated production tools.

MD: I agree with Fréderic. The topical situation is a transition phase with a current, short-term use of PCR, leading to a long-term strategy with "non-fossil" plastic being used for packaging. The biomaterial is a promising approach as it will help contribute to the challenge of climate change. These materials leave an average 30-50% lower carbon footprint than their fossil equivalents.

In addition, the European Association for Bioplastics estimates that the global bioplastic production will represent around 0.021% of the world‘s agricultural area by 2024. Compared with 2019, this will reflect an increase of 26% within five years! In the near future, food residues, inedible plants or cellulose biomass from agricultural practices will improve and consequently reduce the bioplastic footprint. This corresponds to 1 million out of 4.8 billion agricultural hectares.

Our industry also plays an educational role in cooperation with all major players of the circular economy, from suppliers to end users.