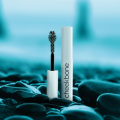

Shadow printing is the new printing technology at GEKA that is an innovative and sustainable decoration technique that avoids any additional usage of foil or ink. It delivers striking surface finishes for packaging, helping customers achieve perfect brand aesthetics.

The qualified process allows partial changes to the surface and is capable of adding matte structures as well as haptic visuals and patterns consisting of lines.

Shadow printing has 360° design application, for a combination of matt and shiny surfaces. This decoration technique is incredibly flexible, allowing complex customized elements and patterns to be applied to bottles or caps. Combined with textures that create vivid surface finishes, customers can create extraordinary aesthetics that reflect brand identity.

In fact, matt and shiny surfaces can be incorporated within the same design for maximum visual effect. When supplemented with hot foil stamp or silk screen printing, the opportunities are almost endless, ensuring uniqueness for any cosmetic packaging.

Thanks to the 360° print without adding any ink color or foil, the process is one of the most sustainable printing processes.

For more information, contact GEKA