If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Greif is pleased to announce the addition of a new high speed production line for small steel drums at its plant in Vreeland in The Netherlands.

Developed to maximize the overall customer experience, the investment will bring significant efficiency gains to the production of small tight head steel drums (12 L to 38 L), improving performance, optimizing lead times and offering delivery flexibility.

Additionally, the plant added a new welding machine as part of the production line, which will further improve the welding quality and is expected to significantly increase overall equipment effectiveness (OEE).

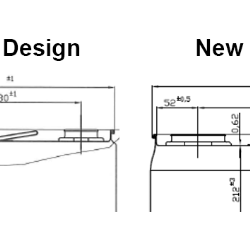

Customers of small steel drums will notice changes in the appearance of the drum: at the neck and in the thickness of the steel which will be a standardized thickness of 0.62 mm to increase the overall strength of the drum.

“Investments such as this, which deliver efficiency gains and enhanced product performance, underpin Greif’s commitment to becoming the world’s best performing customer service company,” Mathieu Postma, plant manager, said.

Greif’s Vreeland facility was established in 1930 and has over 50 employees. The plant specializes in the production of small and intermediate steel drums (12 L to 63 L) which include combi-drums, conical drums, open head drums and tight head drums. Alongside this facility in Vreeland, Greif operates a Paint Factory, established in 1952, which produces internal and external coatings for the packaging industry worldwide.