If this is your company, CONTACT US to activate Packbase™ software to build your portal.

.jpg)

Ishida’s longstanding experience in the development of snacks packaging solutions has been the critical factor in enabling one of the Czech Republic’s leading snacks manufacturers to achieve the high packing speeds required for its new ranges of smaller bag sizes.

POEX, based in Velké Meziříčí and celebrating its 25th anniversary this year, manufactures a wide variety of extruded snacks under both its own brand and for several of the country’s leading supermarkets, as well as for export to Western Europe. Historically the company produced large size packs of 150g and above. However, growing demand for smaller sizes along with the introduction of healthier snack products, including those aimed at children, led the company to seek a solution that could deliver the high bagging speeds necessary to handle the capacity of the extruder.

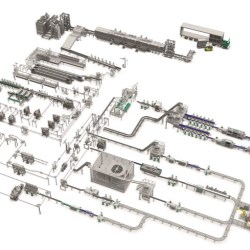

The Ishida iTPS (integrated Total Packing System) is able to pack 15g bags at 125 per minute, with accuracy to within 0.4g of target weight. The solution combines the company’s high speed CCW-RV-214W multihead weigher and advanced Atlas bagmaker, along with a throat metal detector and Ishida DACS checkweigher. The full integration of the system delivers maximum speeds, efficiencies and throughput, ensuring fast and smooth transfer of product from the weigher to the bagmaker.

The proven design of the Atlas bagmaker features an innovative sealing unit that creates tight seals without wrinkles even during high-speed packing. Pressure, temperature and sealing time can be easily set on the Remote Control Unit (RCU) to match the production speed and film characteristics, creating optimum seals for any film.

POEX has a long-standing relationship with Ishida, with 10 multihead weighers, 12 checkweighers and four x-ray inspection systems already installed throughout its four factories. Nevertheless, the company had some doubts as to whether the iTPS could deliver on its speed requirements.

“Although we are well aware of Ishida’s capabilities, even we wondered whether the iTPS could meet the speeds we needed,” explains production manager Jaroslav Caha. “However, because the Ishida solution is specifically designed for snacks applications, it has provided exactly what we needed from the start and we are very happy.”

Another benefit of the iTPS, says Jaroslav, is the fast and easy changeovers that can be achieved.

“Whereas some bagmakers could take up to two hours for a changeover, with the Ishida we can complete this is less than half an hour,” he explains. “This means for an eight hour shift, we are operating for seven and half hours. This helps to maximise efficiencies and throughput, and will allow us to achieve a fast payback on our investment.”

The user-friendliness of the RCU, which also stores pre-sets for all products that the iTPS handles, is equally important. “Our operators are all familiar with Ishida equipment, so the introduction of the iTPS caused no issues,” confirms Jaroslav. “And if for any reason, we need to transfer an operator from one of our other factories to this line, they can very easily take up the new role with no training required.”

The DACS checkweigher provides confirmation of pack weights but more importantly also delivers valuable production information on every pack that can be quickly and easily accessed by POEX to assess overall line efficiencies. This is further supported by Ishida’s IDCS (Ishida Data Capture System) whose powerful software captures the data from every pack that passes across the checkweigher to generate real-time displays and reports which focus attention on major cost-saving opportunities.

For POEX, the speed, accuracy and reliability of the Ishida iTPS solution on small pack sizes are enabling the company to develop a whole range of innovative new snack products. To meet the potential increase in production and packing that this will require, the company is currently considering the installation of a second iTPS to give it the packing capacity of 250 bags per minute.

POEX was established it 1993. Originally specialising in traditional snacks, the company’s product portfolio has grown over the years to include chocolate coated products, confectionery, dried fruits, and cereals, as well as a factory dedicated to the production of poppy seeds.

Today the company has five product divisions spread over four factories. It employs around 230 people, with an annual turnover of approximately 30 million Euros.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(MR).jpg)