If this is your company, CONTACT US to activate Packbase™ software to build your portal.

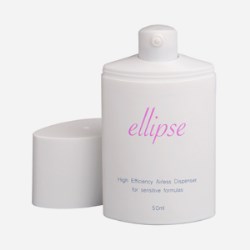

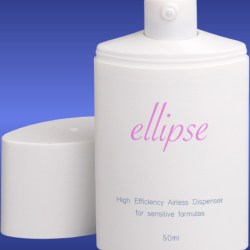

The Airless pouch dispenser from Lablabo is a complete system made of a soft pouch, delivered inside a rigid bottle, combined with a metering pump. Everytime the system is primed, a dose is expelled, the pouch collapses. There is no air intake, no venting hole at the bottom of the bottle. Hence, integrity of formula is protected. Once a dose is expelled, the next one fills the metering chamber and therefore ensures a precise and repeatable dosage.

Thanks to its design, the Lablabo package can easily adapt to all customers’ requests. It eases the filling process (no special equipment needed) and can dispense any viscosity. Lablabo has eight different lines of airless pouch dispensers: Select, Sillage, Ellipse, Easyfoil, Twinbag, Verso, Silhouette and Brio.