Public

LageenTubes Certificates

LageenTubes Image Gallery

LageenTubes Locations

LageenTubes News

LageenTubes Shows

LageenTubes Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

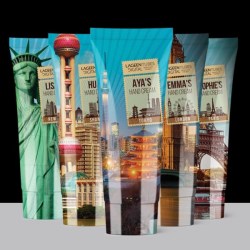

LAGEENTUBES’ new Mono-Material PE tubes are 100% recyclable as a single unit – eliminating the challenges of recycling combinations of different raw materials.

The new mono-material PE tubes are available in a range of lengths and diameters and with a choice of screw and flip-top caps made of HDPE (high-density polyethylene). The tubes are made of food-grade PE according to the strict regulations of US and European authorities and meet ISO 9001:2015 standards, suitable for cosmetics, toiletries, food and pharmaceuticals.

All parts of the one-material tube are manufactured in-house and the tubes are supported by the full range of LAGEENTUBES’ decoration capabilities.

"On the part of cosmetics packaging recyclers, we can only praise LAGEEN TUBES’ initiative,” said Andrzej Kubik from Replas Recycling Plastics. “For plastics technologists it is absolutely understandable that there is a need to separate both material streams, i.e., polyethylene (PE) and polypropylene (PP) in the recycling process, because both admixtures of PP in PE (above 3% by weight) and vice versa (PE in PP) have a very negative impact on the performance of the base material, reducing mechanical strength or resistance to external factors.

The molecular similarity of both materials and their very similar specific gravity (0.85-0.92 g/cm3 for PP; 0.89 - 0.93 g/cm3 for LDPE and 0.94-0.98 g/cm3 for HDPE), which prevents sedimentation in aqueous solution, makes their separation in the recycling process very difficult. For this purpose, either the near infrared (NIR) sample spectrum analysis method or the eddy current method (a variant of aqueous sedimentation) is used. Both, however, have an identification error of more than 3%, resulting in the deterioration of the recyclates described above.

Having mono-material solutions at their disposal, recyclers are able to offer manufacturers re-granulates with much better parameters, highly similar to those of the original materials (virgin) without unnecessary expenditures on separating the PE and PP streams and the possible risk of mixing them in the recycling process".