Public

Lameplast 3D Catalog

Lameplast Catalog

Lameplast Documents

Lameplast Gallery

Lameplast Locations

Lameplast News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Lameplast Group's Barbara Reguzzoni speaks to Webpackaging about its 40 years of expertise in the pharmaceutical industry and how the company has developed from its beginnings as a manufacturer to the complete service provider which it is today.

Barbara, tell us a bit about Lameplast and what the company does...

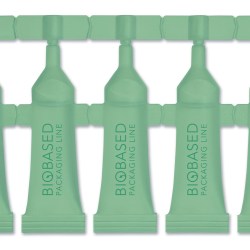

Lameplast Group provides complete, flexible and integrated services for the manufacturing, filling and packaging of pharmaceutical products, medical devices as well as cosmetics, from the design of new containers to the finished product, worldwide

We do everything from the study of the materials to the design and production of the primary container: From the contract manufacturing service to the production of filling and sealing machines. We are the only group that stands as a single reference point and can boast a complete service ranging from the research and development of materials to the creation of a personalised pack, tailor-made to your needs. Lameplast Group is the ideal reference point for pharmaceutical companies as their partner in production - sharing their philosophy, and enabling them to make use of our highly specialised expertise to meet their marketing needs.

The Group offers the experience of 3 firms with different areas of expertise:

- Lameplast is a manufacturer of plastic containers for pharmaceutical and cosmetic products.

- C.O.C. Farmaceutici is specialized in services for the preparation, filling and packing of pharmaceuticals, medical devices, healthcare, personal care and cosmetics.

- LF of America is a US-based company with vast experience in the filling and packaging of cosmetic products.

The Group guarantees maximum quality and safety at all stages of the production process. Every part of the production cycle, including packaging, takes place in a controlled environment and is guaranteed by the experience gained by the company through some 40 years working with the pharmaceutical industry.

What makes Lameplast stand out from other companies?

The group is known for having launched the first single-dose container for ophthalmic use over 35 years ago - an innovative pack that guarantees maximum hygiene and which does not require preservatives. Now we produce the single-dose plastic container on a large scale as it is required for a variety of uses from pharmaceuticals to cometics. Today we are specialized in the moulding of the single-dose containers in various plastic materials and in the filling of any type of sterile product in both single-dose containers as well as preservative-free bottles.

Lameplast Group is a single point of reference from concept to the finished product. Our products are 100% Italian and as I said previously, benefit from over 40 years of industry experience. Thanks to our comprehensive service, the know-how built up and the technology acquired, the wide range of catalogue products and an efficient service worldwide, we are today the most reliable manufacturer of our kind on the international market.

So, is Lameplast primarily a manufacturer?

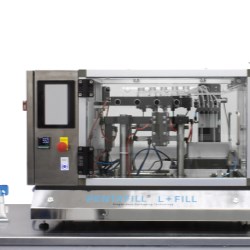

First of all we are contract manufacturers for pharmaceuticals, personal care products and cosmetics. But over time, in order to meet the requirements of the market, we started to offer additional services to satisfy the needs of our customers and now we offer a total service. Lameplast is also able to offer a more complete service by directly supplying its customers with machines for the filling of single-dose containers (Pentafill). In addition, we can offer a complete line of medical devices ready for distribution with the customer's branding and logo. These are CE-branded and can be directly marketed across the EU and also overseas (subject to local registration), in single and multi-dose plastic containers, including ophthalmic preservative-free bottles.

What are your current locations and how are they strategically important?

We have three manufacturing plants, two near Modena and one near Bologna, in the heart of Emilia Romagna, an area that is well known as an important and highly productive manufacturing area in Italy. In this region we have some of the most renowned and appreciated brand in the world including Ferrari, Lamborghini, Blumarine, etc.

You mentioned before that your products can be directly marketed across the EU as well as overseas, what then are the principal markets for Lameplast?

The group is specialized in the manufacturing of single-dose plastic containers and in the filling of products without preservatives both in single-dose vials and in bottles. We sell our products worldwide - Europe including the Mediterranean area and emerging country markets in America, Asia and Africa. We also have a subsidiary in the USA (Florida) specialized in manufacturing and filling of cosmetic products.

In Europe, the Mediterranean area and the Middle-East we work as pharma & cosmetic contract manufacturer and customers appreciate our comprehensive service from preparing the container to having the finished product, ready to be marketed. In Asia and America we sell our empty single-dose containers and filling machines.

Our customer portfolio includes the biggest names in the pharmaceutical and cosmetics sectors; large multinationals and important companies are our customers since years. A demonstration that quality, know-how and our service is always appreciated.

Can you tell us what its like to work Lameplast from a customer's point of view?

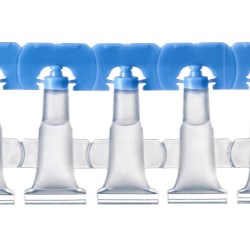

We've been working with a leading Asian pharmaceutical company specialising in ophthalmic drugs which needed a single-dose container with containers and caps in two different colours, in order to help their patients - especially elderly ones or those not able to read or see well - to associate a specific therapeutic effect of the ophthalmic product according to the colour of the cap (i.e. red cap and neutral vial, blue cap and white vial etc…)

Lameplast Group developed a unique and truly innovative strip made with 5 single-dose vials in two pieces, the caps and the bodies, joined together with an innovative technologies.

The other market plus in the project was a recloseable cap with seal ring that remains attached to the vial neck, signalling any tampering of the container and the 'reclosability pin' already inserted in the aperture, which enters in contact only with the product to guarantee greater hygiene.

It's a revolution in the packaging world and this primary container has been awarded with Italian, European and Worldwide Oscars for Packaging. Today it's one of our best-selling products.

What changes has Lameplast undergone over the last decade?

Thanks to our policy of expansion, the group has significantly increased the share of revenues from the foreign market by acquiring new customers, as well as in Europe, the Middle East, Asia, Africa and across America. Today we have customers in over 35 countries in the world and a constantly growing turnover.

How are things going for Lameplast and what do you have in the pipeline?

The year that just ended was very satisfactory - we opened new markets and have been consolidating those that have been opened in the last few years. Our sales force has increased and we are working strongly in this direction. We are also ready to be part of the first fair of the year - next week in Paris. Pharmapack is a very successful exhibition for us from the point of view of visitors, new contacts and prospects.

This year we will celebrate 40 years of activity having grown from a small local company to a Group able to sell all over the word. In recent years, substantial investments have been addressed to make the Group globally competitive with ever faster lines and a performance that meets the demands of the market. The new department for sterile products with high productivity, which opened in 2012, can accommodate up to 6 lines dedicated to fully automated sterile filling of single-dose containers and "preservative-free" bottles. In 2016 we would like to increase our customer base and open one or two new filling lines in our filling department.

At the moment we are also developing new products that will expand our portfolio of products available for distribution. These products are medical devices such as eye drops, nasal products and other personal care products that we grant to customers for distribution worldwide. Several formulations (ocular and nasal sprays), some with innovative molecules, will be available in the coming months.

You're going to Pharmapack. Will you be at any other shows this year?

Yes, we'll be at: Pharmapack Paris from February 10-11; CPHI/Innopack, Instambul from June 1-3; Afi Simposium, Rimini, Italy (an italian trade show focused on pharmaceutical sector) from June 8-10; CPhI-ICSE, Barcelona from October 4-6 and CPHI-PMEC India from November 21-23. With our subsidiary in the USA we will be at Westpack, Anaheim from February 9-11 and also at Pack Expo Int. Chicago from November 6-9.

Barbara, what is your position at Lameplast and what does that involve?

I am responsible for marketing and as a department we work daily with the R & D team looking for new ideas, new products and new innovative containers or plastic materials that may be interesting for a new way of use or innovation.

Every year we develop one or more publicity campaigns with press releases. Another key element of my work is a constant focus on the web and our website. A targeted participation in exhibitions around the world completes our strategy of image.

You've been working with Webpackaging for a few years now. How does it fit into your marketing plan?

We chose to be part of webpackaging because we think it is a portal rich in content and innovation, able to change with the rapid industry trends. The new version is even richer, easier to navigate and intuitive. Moreover, there are many of our competitors and customers. We appreciate the constant updating of content, the publication of the news, the frequent update of info and press releases. It's also important to have a person with whom to interact for every need.

Thanks Barbara, it's been great speaking with you!