If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Madison Polymeric Engineering

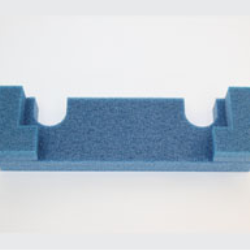

Madison Polymeric Engineering designs total packages from the inside out, including Die Cut Foam, Protective Packaging, Corrugated Packaging, Cases, Crates, Fruit Packaging, Medical Foams and Thermal Packaging.

Why MADISON POLYMERIC ENGINEERING?

Because...You need advice, quotes, samples and delivery - NOW!

Madison Polymeric Engineering (MPE) has over 90 combined years of experience in custom packaging design, engineering and production, located in a 150,000 square foot facility in Branford, CT. MPE has custom foam fabrication capability. Therefore, we can tailor anycontainer to properly protect your product in today's harsh transportation environment.

Our new water jet cutting capability provides for fast turnaround on sampling and quotes. It's ideal for short-run parts, with only minor engineering set-up chrnges.

MPE's has three packaging engineers with over 90 years combined experience, who work directly with you from inception to completion of your project. Our assistance in material selection, design and prototype generation and cost estimation will ensure that your package will be right the first time.

MPE's applications range from medical instruments, such as scopes, to military cases, optical instrument packaging, computer and peripheral cases, oceanographic equipment cases and aerospace packaging. We also specialize in reusable containers, sales demonstration cases, test equipment cases, broadcast and video equipment cases and laboratory equipment cases.MPE is expert in hot wire profile cutting of expanded polystyrene (EPS) to fabricate protective packaging inserts as well as custom thermal packaging to keep fine foods and beverages from perishing.

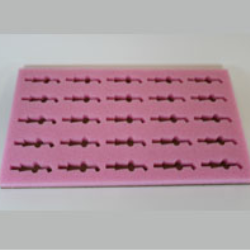

MPE's custom foam inserts include die cutting and profile cutting of the following materials: urethane foams, antistatic urethane foams, conductive foams, polyethylene foams, antistatic polyethylene foam, convoluted urethane foam, high density cross-linked foam and expanded polystyrene (EPS) foams. We also have the capacity to route EPS and cross-linked foams on our computer programmed multiple head router. Our specialty foams include flocked foam which is a flocked material laminated to urethane foams of various densities and colors.

MPE's manufacturing capabilities include:

- 5-axis Waterjet Cutting

- Precision Die Cutting

- Computer Programmed Profile Cutting

- Hot Wire Profile Cutting

- Computer Programmed Multi-Head Routing

- Fabrication

- Heat Sealing

- Sonic Welding

- Wood Working