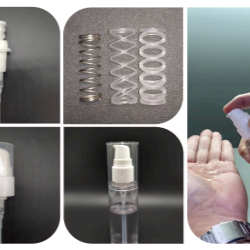

At Magnetic Packaging, we firmly believe that a "long-term cooperative relationship cannot exist without stable quality."

In our pursuit of high-quality products, we prioritize both research and development (R&D) and quality considerations. Magnetic Packaging has been honoured with international certifications, including ISO 9001 for Quality Management and ISO 14001 for Environmental Management. Moreover, our facility has successfully passed factory inspections conducted by several globally recognized manufacturers.

We meticulously ensure that specifications are met at every stage, from product development and mock-up to manufacturing, operational environments, and process control. Our commitment extends to stringent safeguards, including maintaining environmental cleanliness and conducting quality inspections at every step to guarantee the stable manufacture of our products.

Visitor Pathway

Our tour passages are designed to facilitate smooth customer movement without introducing dust into production areas.

Clean Room

Our production specifications meet medical-grade standards, and our production environment operates as a cleanroom.

Restricted Access

To prevent contamination, cartons are not permitted in production areas.

Tray Clean Machine

We employ dusting machines to eliminate static on corrugated foam, preventing dust and hair from adhering.

Fitting Room

Every individual must change into clean clothes in the designated changing room before accessing production lines.

Air Shower

A wind shower before entering production lines ensures that no contaminants are introduced into the facility.

QC Check

Production personnel conduct regular and quantity-prescribed quality assurance checks on our products.

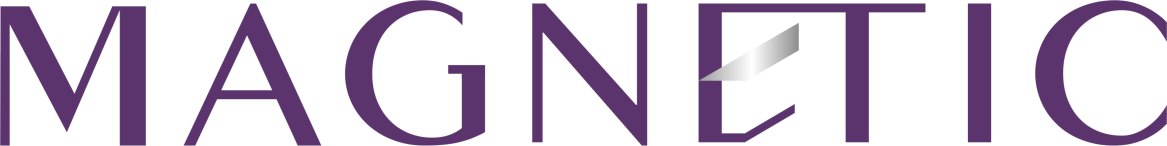

Auto QC Machine

No expenses are spared in acquiring "automatic inspection machines" to ensure that every part meets our high standards.