If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Werosys is the latest company to employ Meech’s static control solutions, with the installation of thirty Hyperion 929IPS anti-static bars in its production environment. The Danish label and web converting machinery manufacturer chose Meech’s systems for their excellent ionisation properties and seamless integration with its intelligent converting equipment.

Based in Allerød, Denmark, Werosys specialises in the development of innovative equipment for the global label converting and finishing industry. The company was established in 2013 by a group of professionals with decades’ experience and knowledge of these sectors.

“Werosys was founded on a shared passion: to rethink label production and deliver significant value to the market by adopting an integrated approach to converting,” explains Søren Pedersen, Chief Commercial Officer at Werosys. “Ideally, a digital press should be able to run continuously with minimal operator involvement and without stops for setup and job changeovers. The solution we propose is what we call ‘intelligent converting’, a converting line that automatically separates multiple jobs on the same roll.”

He continues: “With our systems, you can run a series of jobs from one centralised PLC/HMI, whether it’s selecting varnish, importing the die cut shape to the laser, adjusting the automatic knife system or set up the rewinding. The result is reduced waste, reduced costs, an optimised production and enhanced capacity.”

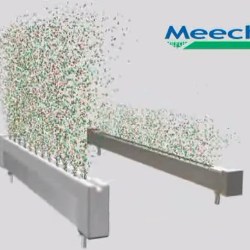

It is this move towards an automated production environment that led to the installation of thirty Hyperion 929IPS anti-static systems on Werosys’ converting lines over the course of two years. The bars, which also allow easy integration and require minimal operator intervention, were a perfect fit with Werosys’ automation philosophy.

Bjarke Gerdes-Nielsen, CTO and founder of Werosys, comments: “The online monitoring capabilities of Meech’s technology fits perfectly with our full integration approach, where we are able to remote control and run diagnostics on machines from our site in Denmark via standard Internet connection. This means that we can support our customers by planning preventative maintenance schedules to ensure that our machines do not have unscheduled break-downs and thereby offer the highest OEE (Overall Equipment Efficiency) in the business.”

“Like our company’s founders, Meech has decades’ experience in the label and converting sectors, so we knew straight away that we could benefit from its static control technologies,” continues Søren. “They have been a part of our business since the company was created – the first label converting line we commissioned back in 2014 included a Meech anti-static bar.”

The Hyperion 929IPS is a compact pulsed DC ionising bar with Integrated Power Supply (IPS), with default settings that allow quick and easy installation and use on label production lines. A 24V plug and play bar, it provides excellent static elimination for short to medium range applications (up to 500 mm). The adjustable performance and compact dimensions of the bar are also among the key benefits that appealed to Werosys.

“The Hyperion bar is an ancillary system that adds significant value,” concludes Søren. “We sell it as a standard option that can be built into our converting systems and we strongly recommend its inclusion to ensure all static charges are removed from the web.”

By Stewart Gordon Smith, Business Development Manager (Meech International)

The elimination of static charges should be a fundamental part of the quality control measures adopted in flexible packaging. Cleanliness is a critical issue in a wide number of industries – especially food, medical and pharmaceutical – with customer demands constantly increasing the required standards. The manufacturers that fail to meet these standards risk losing out to more pre-emptive competitors in a progressively driven market.

With no static control solution in place during production, the more issues the charged material is likely to cause. First of all, the presence of static will attract contamination onto the film from machine frames and from the process environment. This can lead to the disposal of tainted products, as well as high rejection rates that can have an effect on customer loyalty. Static can also cause tension and web alignment problems during printing and rewinding processes. Other issues instead raise a number of health and safety issues, such as operator shocks or, where solvent based inks are adopted, the risk of ignition of flammable gasses and substances.

In the flexible packaging process, filmic substrates require corona treatment to allow the ink to adhere to the material’s surface. However, the treatment is likely to produce multiple electrostatic charges as a result of the creation of the curtain of corona plasma, which is generated by applying high voltage to a sharp-tipped electrode.

Blown/cast film will produce electrostatic charges on the material’s surface as the product cools to ambient temperature. When the corona treatment is applied, the static charges are magnified as the material passes through the high voltage plasma field. These charges can result in an increase in web tension, as the material tries to bond to path rollers and nip drive rollers, further adding to the charges present on the film. The last point of generation occurs when the film is wound into rolls, with each stratum of film adding another layer of statically charged material, as the roll increases in dimension.

The prevention and elimination of these charges can be easily achieved by installing an ionising bar (also referred to as an anti-static system) that will ensure the material’s surface remains void of any contamination, ensuring print quality is maintained and health & safety is observed.

Meech’s Hyperion range of ionising bars is designed to provide first-rate static control solutions even under the most extreme operating requirements. With the need for flexibility to control charges on high speed process lines and the requirement to work over long range, the Meech Hyperion bars can also provide closed loop automated monitoring. During the rewinding of material the performance of a Hyperion bar can be optimised, using distance or feedback monitoring options, to ensure consistent static control is maintained at all times.

Meech International has announced the latest addition to its Hyperion range of static control systems, the 959IPS ionising air curtain. The new unit is designed to provide effective static neutralisation and dust removal in a wide range of industrial applications across the plastics and packaging industries.

The 959IPS has an IP66 rating and is a hybrid solution that comprises a Hyperion 924IPS anti-static bar mounted on a Meech energy saving air curtain. The combination of the two technologies results in a high speed laminar sheet of ionised air.

“The Hyperion brand has been about adhering to three core principles: precision, performance and productivity,” explains David Rogers, Technical Director at Meech. “The 959IPS delivers on that promise by combining the key features of our static control equipment and Meech Air Technology (MAT).”

As with other products in the company’s MAT range, the 959IPS is an energy efficient solution and cuts compressed air demand by up to 70%, significantly reducing running costs. The air curtain component also ensures a noise reduction of up to 50dBA is achieved, which is significantly lower compared with “open pipe” systems that consume vast volumes of compressed air.

The 959IPS shares most of its features with those found in other Hyperion products. Running on a 24V DC power supply, the system’s compatibility with the Hyperion BarMaster programmer means the output voltage, frequency and balance can be adjusted remotely by the operator, therefore making it suitable for a range of applications. The unit also includes Meech’s Ion Current Monitoring technology (ICM), which ensures high performance is maintained with local and remote alerts for when the bar requires cleaning.

“The 959IPS is a welcome addition to the Hyperion brand,” concludes David. “Thanks to this latest innovation, we’re able to broaden further the capabilities of the range, as well as help businesses address their static control needs.”

Xeikon has optimised its digital press solutions with multiple installations of Meech’s CyClean™ non-contact web cleaning systems. Ideal for high speed presses and with an ability to handle virtually any substrate, CyClean ensures spotless webs are maintained on the Xeikon 3050 and Xeikon 3500 presses, part of the company’s 3000 series used for wall paper production and folding carton applications.

Founded in 1988, Xeikon has established itself as an innovator in digital printing technology. The company is committed to delivering high quality web-fed digital colour presses to a number of sectors – such as label, packaging and commercial print – which are sold worldwide through a value-added distributor network.

“When speaking to prospective customers, we would often hear printers comment on the amount of dust present on their printing presses as a result of the production environment they operate in,” explains Filip Weymans, Director of Segment Marketing for Labels and Packaging at Xeikon. “With end product quality being heavily scrutinised, it is imperative to ensure that our presses remain spotless. For this reason, we saw an opportunity to optimise our offering by implementing an automated solution that would guarantee the web’s cleanliness, plus reduce operator maintenance.”

This has led to the installation of a number of Meech’s CyClean web cleaners over the past two years. CyClean is a compact, non-contact, double-sided blow and vacuum-based system which flows contaminants into an inline filter unit. It can clean webs up to 3m in width, is capable of removing 0.5 micron contaminants and has a small footprint that enables it to be fitted into confined spaces.

Its compact size makes CyClean ideal for installation on the Print Machine Supply unwinder of the Xeikon 3050 and Xeikon 3500 roll-fed digital presses. As the web is unwound from the roll, it is passed through the web cleaner before it enters the digital press.

Integrated static control on the entry and exit of the cleaning head guarantees a thorough, long-lasting cleaning process. The in-built AC ionising bars neutralise all static charges on the web and ensure easy breakdown of the bonds holding contaminants to it. The risk of re-attracting contaminants to the cleaned web surfaces is also significantly reduced.

“We sell Meech’s web cleaners with our presses as part of an optional package,” says Filip. “It optimises the overall production process and we strongly recommend the CyClean’s inclusion in all of our sales, as it adds significant value.”

Filip is also keen to comment on the partnership with Meech, who has gone on to become an Aura Partner for Xeikon since the CyClean installations. “The Aura Partner Network is a robust and fully encompassing group based on non-exclusive relationships with industry-leading partners,” he explains. “Meech has been extremely supportive in helping to explain to customers the importance of having a clean web in the print industry. We’ve been able to do this by running test trials and demonstrations at networking events, such as Xeikon Café.”

Last hosted in Antwerp, Belgium in March 2015, Xeikon Café functioned as an informal knowledge exchange platform, where guests could discuss trends affecting the print, packaging and converting sectors. During the event, Meech explained to visitors how web cleaning could minimise wastage and achieve higher levels of productivity on digital print applications, as well as highlighting a move towards non-contact systems, such as CyClean, in the label market.

Filip concludes: “Thanks to CyClean, we are in a position where we can sell our presses in full knowledge that the customer will not have to worry about the presence of contamination on the web. We are more than happy with the system, not to mention the service and support provided by Meech.”