If this is your company, CONTACT US to activate Packbase™ software to build your portal.

A team of engineers and designers study and personalise all products through high quality rendering and prototypes: an additional service that allows customers to safety choose the design that best meets their needs.

Metalchimica is able to decorate any type of plastic material.

Various solutions are available and the product is personalised according to customer needs.

- Custom prints:

- hot printing;

- traditional and UV silk screening;

- metallic finishing;

- lacquering;

- painting;

- labelling;

- pad printing;

- sleeving.

- A wide range of colours and visual effects.

- Soft touch tactile effects and Braille printing.

- Zero-toxicity paints.

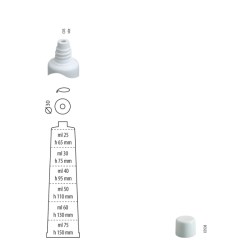

TUBES

Paints: glossy and satin finish paint available on all diameters.

Print: 6 offset colours, 3 silk screen colours + hot printing.

Capsule decorations (row, logo, print).

Metallic capsule finish.

Flip-top push on capsule sleeving.

Ability to print the entire tube body, from the shoulder to cut, with three pint technologies (offset, silk screen and hot printing), without reserves.

Possibility of using all masters, including iridescent, pearly and metallic colours.

Metalchimica is now able to decorate any type of plastic material. Thanks to its know-how, the company can promptly and professionally meet single customer needs, creating multi-colour silk screen pad printing and hot stamping prints even on more complexly shaped products. Furthermore, the wide range of zero-toxicity paints enhances the product, guaranteeing precision in minimum detail.

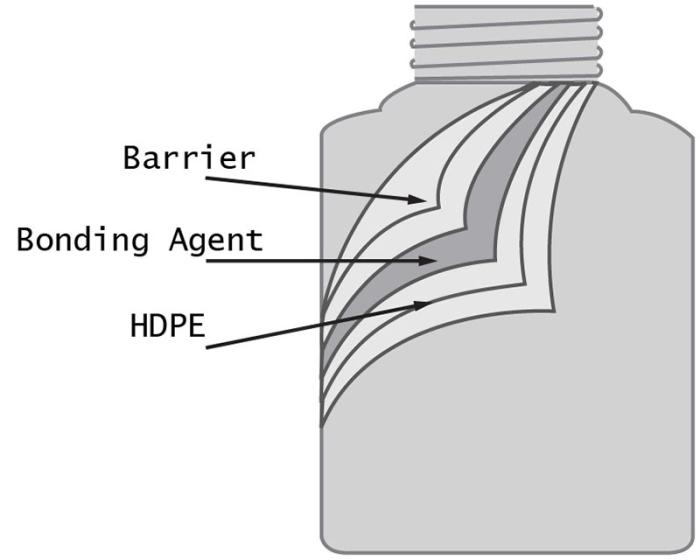

Coex, the barrier effect

Metalchimica is the leader in Coex product production, the technology that allows for the production of multi-layer plastic containers with materials such as Evoh or polyamide with minimum thickness that provide the barrier layer function.

Thanks to these solutions, the container becomes resistant to agents aggressive to plastic, like solvents or impermeable gas, increasing the shelf life of products sensitive to oxygen and preserving the fragrant essences that would quickly migrate outwards from traditional containers.