Public

Company & Packaging News

Gallery for Packaging Projects

Locations

MingFeng 3D Studio

MingFeng Catalog

MingFeng Packaging Companies

MingFeng Packaging Documents

MingFeng Packaging Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Luxury packaging company, MingFeng is well known for its intelligent designs and its manufacturing of 'green' packaging. Now the company has taken the next step by introducing biomass composites and products into its offering.

Renowned for standards that even the most demanding clients appreciate, the company's biomass composite products open up new options for sustainable packaging.

What are biomass composites?

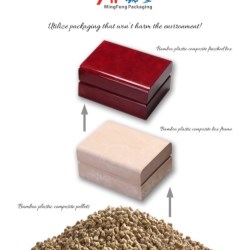

Biomass composites are essentially organic substances which are combined with one or more substances to create a material with a bio-base. It's still a new technology, both for MingFeng as a company, and also the market as a whole.

The two principal features of biomass composites are that they are produced by utilizing organic substances and that at the end of their functional life-time as a product, they can be broken down as they are either partially or completely degradable, according to the composite.

Which organic products are used to create biomass composites?

A great variety of natural crop substances can be used such as wood, bamboo or rice husk, and as an added benefit, natural waste products are also viable options. As well as cereal crops their residues can be incorporated, along with other typical plant waste. Animal waste and urban garbage, even residue from forestry and agricultural processes can all be taken advantage of. All of these resources are renewable, sustainable options so that they are a better choice for the environment.

How does MingFeng create and use biomass composites?

In the simplest terms, we use grains, fibers, husks and organic products to form pellets. These can then go through extrusion, co-extrusion or injection processes to produce packaging and other commodities.

Our biomass composites have achieved a number of safety certifications to guarantee their quality and safeness for use: Flame retardant performance, solvent residue, acid/salt proof and also food safety.

Which products and markets can utilize MingFeng's biomass composite material?

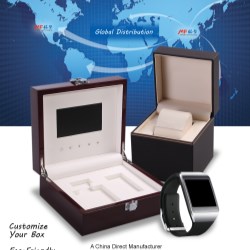

Ming Feng is specialist in the production of luxury box products. That includes paper, rigid and plastic boxes. The company's work is well known globally for limited edition offerings. The company was honored to produce the presentation boxes for the medals and coins presented at the 2008 Beijing Olympics. We were also the exclusive medal packaging supplier for the 2012 London Olympic games as well as the official souvenir packaging supplier for the 2016 Rio Olympics.

Other limited edition projects for which the company is acclaimed are commemorative boxes for national coin mints around the globe.

Boxes are ideal for production with biomass composites. Other products that can successfully employ biomass composites are electrical appliance parts, such as covers for mobile phones or vacuum cleaners, automotive parts for use inside the vehicle, hard cases for musical instruments, tertiary packaging for transportation, and more. Crates and pallets are ideal for production with biomass composite materials and in addition to their production with sustainable material, they can also be reused, therefore prolonging their usage lifetime which saves on resources.

There are many products and markets which can benefit from biomass composite applications because it offers excellent impact strength and also safe for food contact, so it can be utilized for tableware, decorative wine racks, and even outdoor applications.

How can biomass composites be used in outdoor applications?

Decking and fences, park benches and outdoor seating, pergolas and pavilions, trash can covers and even planters and plant pots are all viable outdoor applications. Biomass composites are incredibly hard-wearing and lend themselves really well to gardens as well as parks.

The composites can go through injection, extrusion, co-extrusion, and compression molding processes according to the product required and a wood finish offers an ideal surface for outdoor applications. Transfer printing, painting and more are also options for a different finished look.

According to the composition of the composite, it benefits from superb heat resistance and is certified for its flame-retardant performance, is very strong and of course, can be composted at the end of the product's lifetime.

What are the biomass composite options available?

MingFeng offers 4 options - mPLA, PLA/NF compounds, PBS/NF compounds and PP/ST compounds which are all suitable for tableware, container and packaging box applications. Each option has slightly different characteristics.

Scientists are employed for the creation of different compounds to ensure that customers can select options according to their requirements. The company is well known for its scientific approach to production and inspection of its work and its production management process that delivers a 'zero flaw' package.

Biomass composites are incredibly close in mass to non-biomass composite products so that the consumer cannot notice a difference. Production timeframes too are comparable so that customers can choose a highly comparable product that is sustainable.

.jpg)

.png)

.png)