If this is your company, CONTACT US to activate Packbase™ software to build your portal.

MMC Packaging

MMC Packaging, a Tekni Plex business, is a Canadian company that manufactures & supplies a complete range of post-moulding automation equipment for the caps & closure industry such as cap lining machines (wadding machines), assembly machines, closing machines, slitting machines as well as vision inspection systems and peripherals.

Nearly 30 years of post-molding automation

MMC Packaging has become the leading supplier and manufacturer of state-of-the-art turnkey post-molding systems for cap and closure manufacturers. Located in Laval, Quebec, MMC employs over 65 engineering, sales, production, customer service, and support staff that always take that extra step to ensure product quality and customer satisfaction.

You make the cap. We handle it.

MMC Packaging has supplied over 900 turnkey systems worldwide and over 4,000 individual pieces of equipment. In a market that is constantly looking for innovative caps & closures, the dynamic MMC team takes time to understand your special machinery requirements and has the capability to develop new and improved methods for specific after-molding functions.

Our mission is to provide custom automation solutions to the closure industry.

Why should you choose MMC Packaging? Because we listen to our customers; we stand behind our products; we offer innovative solutions; we supply reliable and durable equipment; we respond quickly and deliver on time.

Products

Cap lining/wadding machine

MMC Cap lining machines are designed and manufactured to stamp out lining material disks from rolls of material and install the disks in caps at rates up to 1200 caps/minute (depending upon cap size and design.)

MMC Cap lining machines are designed and manufactured to stamp out lining material disks from rolls of material and install the disks in caps at rates up to 1200 caps/minute (depending upon cap size and design.)

Types of closures: food and beverage, pharmaceutical and nutraceutical, personal and household care, automotive, agrochemical and more.

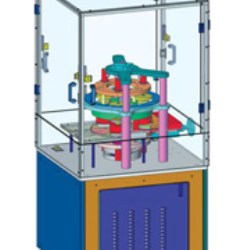

Assembly machines

MMC designs and manufactures assembly machines that can assemble 2-piece and 3-piece closures at rates up to 1200 caps/minute.

MMC designs and manufactures assembly machines that can assemble 2-piece and 3-piece closures at rates up to 1200 caps/minute.

Types of closures: 2-piece child resistant closures; 2-piece & 3-piece sports caps; 2-piece non-dairy creamer caps; 2-piece hinged dispensing closures for condiments; antacids and large count chewing gum packages; various styles of multi-piece beverage caps.

Closing machines

MMC designs and manufactures closing machines for a variety of closures with various hinge styles and latching features that can reach rates up to 350 caps/minute. Our closing machines use repeatable and highly efficient techniques to perform intricate closing functions.

MMC designs and manufactures closing machines for a variety of closures with various hinge styles and latching features that can reach rates up to 350 caps/minute. Our closing machines use repeatable and highly efficient techniques to perform intricate closing functions.

Types of closures: flip-top closures for condiments; dispensing closures for the hair care market; rectangular coffee closures; single-door and twin-door closures for spices and grated cheese; single-door and twin-door closures for non-dairy creamer; beverage closures; custom designed hinged closures.

Slitting and band folding machines

MMC designs and manufacturers cap slitting and band inverting machines that score the side wall of plastic closures either with an arched slitting blade or a cut-to-post technology. The slitting & band folding machinery can reach rates up to 1600 caps/minute.

MMC designs and manufacturers cap slitting and band inverting machines that score the side wall of plastic closures either with an arched slitting blade or a cut-to-post technology. The slitting & band folding machinery can reach rates up to 1600 caps/minute.

Types of Tamper-Evident closures: beverage closures, automotive and chemical closures, sports caps, pilfer caps and more.

Vision Control

The MMC Vision system captures defects before your customers do. MMC Packaging is the only manufacturer of automation equipment with in-house optical specialist and software engineers. Our interface provides a user-friendly experience, allowing your operators to navigate in a natural and intuitive manner. The MMC-Quality through vision (MMC-QTVision) can reach rates up to 2400 caps/minute.

The MMC Vision system captures defects before your customers do. MMC Packaging is the only manufacturer of automation equipment with in-house optical specialist and software engineers. Our interface provides a user-friendly experience, allowing your operators to navigate in a natural and intuitive manner. The MMC-Quality through vision (MMC-QTVision) can reach rates up to 2400 caps/minute.

The QTVision can detect the following defects:

Liner detection: missing/inverted liner; half-moon; off-centre; foreign debris; warped caps and splice detection and more.

Closure defects: wall inspection; color inspection; short shot; broken caps and more.

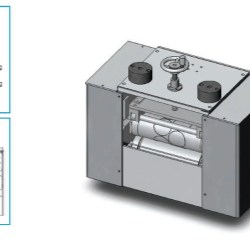

Multi-purpose frame (MPF)

MMC has designed and manufactured a cost-effective machine that meets the same high standards for quality, technology, reliability and robustness as the rest of its product line. The MPF can be customized to perform various functions in one compact design. System capacity: 1-across, 53mm nominal diameter and rates up to 85ppm.

MMC has designed and manufactured a cost-effective machine that meets the same high standards for quality, technology, reliability and robustness as the rest of its product line. The MPF can be customized to perform various functions in one compact design. System capacity: 1-across, 53mm nominal diameter and rates up to 85ppm.

The MPF can be adapted for several types of post-molding operations: punch and die lining; rotary die lining; pre-cut liner disk insertion; multi-piece custom assembly; cut-to-post tamper evident band slitting and/or band folding; closing caps with various hinge styles and latching features.