If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Packaging plays an important role when marketing a new product. Besides the overall design of the packaging, questions that should be asked are:

- How can the product's shelf life be prolonged?

- How can leakage be avoided?

- How can tamper evidence be guaranteed?

If a company has to ask any one of these questions it is highly probable that a liner is required. How the liner can be inserted into the cap and which company can manage the task should be the next questions asked.

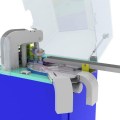

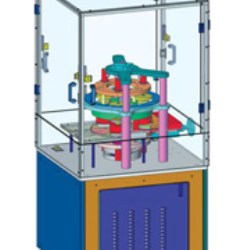

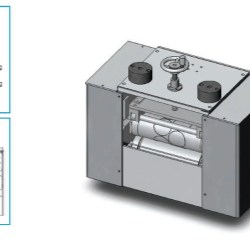

MMC Packaging was one of the first companies in North America to have designed and manufactured automation equipment that cut and insert liners in caps at high speeds for customers both in North America and throughout the globe. Over the last 20 years, MMC Packaging has been a worldwide leader in cap lining machines engineering reliable and durable machines that can withstand the harshest conditions.

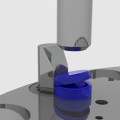

Known for their durability and longevity, MMC Packaging's cap lining machines have evolved over the years with new technologies such as the "Rotary die" cutting method, a technology that has come to be appreciated by customers especially for its ease of operation and changeover. One of the company's customers still has their original equipment which has since lined over to 2 billion caps resulting in a pretty impressive return on investment.

No matter what type of cap or closure needs to be lined, MMC Packaging is able provide comprehensive solutions for post-molding automation.