If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The President of MMC Packaging, Philippe McNally, will be presenting at the forthcoming AMI Plastics Plastic Closure Innovation conference in Berlin, Germany. The topic, "Planning for automation in closure design: Improving part quality and uptime" will highlight post-molding operations which can save manufacturers both time and money.

McNally comments:

"Post-molding operations are often considered only as an after-thought rather than an integral part of the initial stages of closure and mold design. Post-Molding automation is the last to touch the cap and therefore consulting cap handling experts helps closure manufacturers to save time, money and most importantly may help them avoid costly issues in the long run."

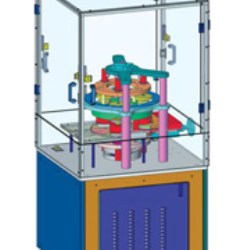

Typically, it is the closure manufacturer that designs the part and then shares the details with its preselected mold manufacturer in order to finalize the design. In order to complete the job of mold design, the press specifications are also preselected and submitted to the mold builder. Post-molding automation selection tends to happen after these steps are completed.

When looking at caps, post-molding automation engineers analyze the numerous features that facilitate or limit the handling capabilities of the parts: In some cases the impact is minimal, in others, the input from the automation engineers can complement the part design process. The integration of some simple changes can prove fruitful for improved processing and part handling throughout the post-molding automation equipment selection.

During his presentation at the conference, McNally will demonstrate how a collaborative approach to closure design improves the overall efficiency of the program whereby an effective automation solution can be found between experienced teams of cap manufacturers, mold engineers and post-molding automation engineers.