If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Naiara Loroño at Nortpalet takes us through the firm's history and current offerings to showcase just what it takes to be a powerhouse in the tertiary packaging space. There's a lot more going on in pallets than you think.

Naiara, can you give me a brief summary of what you do at Nortpalet?

I joined the company in 2013, my main role then and now has been to develop the company’s whole commercial and marketing strategy. Our main goal was to develop a well-known brand in the plastic pallet industry for all of Europe and to diversify our sales into different product ranges and markets competing with the most successful international players. Nowadays, we are present not only in Europe, but also in African countries and in South & Central America.

How did Nortpalet start out and then grow?

Nortpalet was founded in 2006 and the initial idea was to set up a pooling company for plastic pallets, including the in-house development and production of our own solutions. However, while developing our first plastic pallet, we were approached by a big pool player giving service to the biggest retailer in Spain, which changed our initial business model and converted us into purely a producer of plastic pallets. From that moment, we have been developing more and more solutions that complete our current product portfolio with more than 60 different models. There are different ranges of plastic pallets to cover the different needs and/or applications of any type of industry, and Nortpalet wants to cover them all as much as possible.

How did the initial phases go?

Quite well. As mentioned before, with our first product – a repairable, plastic half-pallet that was presented at a forum, AECOC – we achieved an important contract and our products can still be found in a major Spanish supermarket chain. During some years this was our main activity, but in 2013 we started to diversify with the launch of new products and to open up to new customers and markets.

Although all our experience to date has been in plastic pallets, we have worked on designs and projects for some sort of reusable transport element, including boxes, dollies, and trays; anything used to transport goods, made of plastic. Furthermore, we do have a subcontracting business unit in which we produce multiple different plastic pieces (covers for electrical appliances, automotive parts, etc).

We cover the entire cycle of the product from the conception of a solution to the manufacturing and final repair/recycling of the product at the end of its life cycle. We have our own R&D department and our own in-house material laboratory for the development and validation of the different materials that are going to be used.

Currently, what kind of facilities do you have?

At our production site, we have all the necessary facilities to develop, manufacture, validate and test products internally, including an impact table, a roller path, racking shelves and a quality control station.

Since the beginning, Nortpalet has been concerned about sustainability and zero waste policies. Therefore, apart from being one of the pioneers in the development of repairable solutions in plastic pallets, we have a recycling facility to recover the pallets at the end of their cycle life. By processing them, we are able to recover the raw materials of this waste to introduce them into new units.

Why all the specialized equipment for pallets?

All our products are developed using Ecodesign techniques, this means that we conceive them as sustainable solutions, under the philosophy of the 3R’s: Reduce, Reuse, Recycle. All our products have been conceived to be taken apart at the end of their cycle life.

Among our ranges, we can have pallets which are repairable. This doesn’t mean that you can fix the pallet by welding, cutting or adding plastic. They are products which have spare parts, that allow the customer/user to interchange one of these pieces and extend the cycle life in case of impact/breakages in a quick, easy, and cheap way. For this purpose, we have developed the machinery and gear needed to carry out this process, to give our customers a complete and integrated service.

How many of your products are recycled?

Almost 95% of what we manufacture is produced with recycled plastics (recycled Polypropylene or recycled Polyethylene).

Are there any strictures to using recycled materials?

Sometimes, in certain sectors such as pharmaceuticals or food industry, the pallet is manufactured from virgin materials because they require food contact in the materials used. Apart from that, recycled plastics can be used without any problem as plastic pallets are for tertiary packaging. This means that normally the goods are already packed in other packaging containers and not in direct contact with the pallet. There are consequently no restrictions with regard to the materials of the pallet.

What sort of products do you offer today?

During the initial years of activity, we started with one customer and one product. We've obviously grown since then, and nowadays we have more than 60 different models in our catalog and more than a thousand customers worldwide.

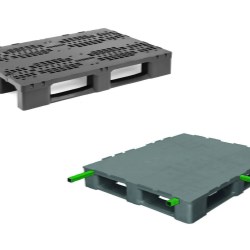

We divide our catalogue into four different ranges of products:

- Lightweight pallets, which are the most economical option for shipping and exports. Unlike wood, plastic pallets have advantages such as complying with ISMP-15 regulations and they do not need documentation or certification.

- Medium pallets, which are reusable and economical.

- A Heavy Duty range, for those who need higher capacity loads and durability.

- Hygienic pallets, made from virgin materials for hygienic applications.

In general, we offer the standard dimensions of industrial-sized pallets, Eurosize pallets, half-pallets, and quarter-pallets. Moreover, we also have special dimensions such as the 1,300mm by 1,100mm.

All our pallets can be customized for our customers in different materials and colors, logo printing or engraving, different options for the rims, labels, RFID tags, etc.

How reusable are your products?

All pallets can be reused, but reusability will depend on the type of application/circuit/conditions in which the pallet will be used.

Lightweight pallets are conceived to be cheap and light, so reusability will be less than reusable pallets. The heavier the pallet the stronger it is, which affects the durability.

For the upper ranges of pallets, we seek to offer economy in cost per movement or per use in the long term. In the short term, there is always a bigger initial investment cost, but due to their durability, these pallets can be more economical than wooden pallets in the long term as their life cycle can be up to five times longer.

Why is the life cycle that much longer?

Plastic does not normally contain parasites or bacteria. The material can be washed. It does not alter in shape or weight with moisture or water. It does not deteriorate. It doesn’t leave splinters or nails, making it much safer for workers to handle. Plastic does not leave residue on production lines, so the maintenance cost level is reduced. The visual appearance of the area around the pallet is also improved, both near production lines and in the stores.

How are your pallet sales this year?

This 2018, our forecast is to grow our sales 15%. The first quarter of the year has been very satisfactory, mainly due to the achievement of new customers and the growth of the existing ones. Also, we are working on numerous bespoke projects which we hope we can convert into new successful business cases, as we already did in the past by developing two different repairable half-pallets in plastic for two of the main pooling companies.

What are your sales like on an international scale?

Since 2013 we have been opening new markets. We began in the European Union, with exports to the United Kingdom, France, the Netherlands, Germany, and then sporadically to the Mediterranean islands, as well as Italy, Switzerland and Portugal. These are important markets for us because pallets as a product, to date, have been very bulky. Due to the level of transport costs, efficiency is essential. It is important to be competitive or have highly innovative products that other manufacturers do not have, which allow us to sell at greater distances.

Since last year, we have branched out to cover North Africa and we also have agreements further south on the African continent as well as Central and South American countries.

We currently export to more than twenty countries. In just over five years, we've gone from 0% to about 45% of our income coming from abroad.

Is there a big demand for plastic in your home country of Spain?

Spain has a market that is increasingly growing, but the use of plastic pallets is not as widespread as in Germany, for example. In Northern Europe, they strongly favor the use of plastic pallets. There is a greater awareness of the numerous benefits. In Spain, the price issue is still a big factor.

Do regulations favor plastic pallets?

Yes, there are many direct regulations that strongly support the use of plastic pallets, mainly in the food industry. Nevertheless, there are other industries that historically also consume plastic pallets due to their numerous advantages, including the automotive, pharmaceutical, and chemical sectors. Most recently, we've seen retailers, logistic firms, and pooling companies looking into plastic pallets as a good alternative to the conventional ones.

Would you say that wood pallets are more disposable?

Yes, although wooden pallets can be repaired, at the end of the useful life there is one point where they need to be rejected as they cannot be repaired any longer. When talking about plastic pallets, once they end their life cycle, they can be recycled to recover the plastic, turning the waste into valuable resources.

Do you think wood pallets will fall into disuse?

No, I don’t think so, not in the near future. Today, about 90% of pallets are made of wood. Another 5% are plastic and 5% are cardboard, metal, or other types of materials. There is evidently a growing trend in using plastic pallets and these percentages will vary in the medium and long term, but it is really difficult to forecast what the breakdown will be in future.

Are plastic pallets really better for the environment?

Look, plastic waste is a problem in our society nowadays, like all the plastic waste we use at home daily: caps, bottles, films, trays, amongst other things. There are many plastic products that end up in the yellow container, because they are packaging. Packaging has a very short cycle life. From when it is produced in a shampoo factory to when the shampoo is thrown into the yellow container, only six months have passed, on average. A bottle of water has an even shorter lifespan. A pallet of recycled plastic picks up from there. You take packaging that ends up in the container in the garbage in less than six months and it is converted. It is put into a process where a second life is given to the plastic. Some pallets weight 23kg, so imagine how much plastic packaging is needed to convert it into a pallet. A reusable pallet can last up to ten years. So, we're taking waste that could end up in landfills or the ocean and converting it into a pallet that has a long lifespan, it can be used again. We can continue to give life to that plastic and that is what we promote.

Furthermore, recycled plastic pallets reduce carbon footprints, reduce dependence on fossil fuels, and are simply more sustainable.

Is there a tendency for the market to use lightweight or heavy-duty pallets?

Both. Lightweight pallets are usually used for export worldwide, because they are equivalent to wood pallets. By using plastic pallets, you avoid ISPM 15 regulation paperwork, also to ship goods to customers when there is no return of the pallets. On the other hand, heavy-duty pallets are good for internal use or closed loops between sites or customers.

How would you say that Nortpalet differs from other suppliers, apart from the whole plastic or wood choice?

Nortpalet is a young company with a young team within a mature sector. The plastic trend is growing, though. There are players who have been around longer than us who were the pioneers, who have been pushing plastic pallets for twenty years. We are trying to offer something more flexible than those big companies. Above all, we aim to support our customers throughout the whole purchasing process, because in the end, almost everyone is making the change from wood to plastic. You have to follow things up and help them, you have to guide them. We like to be very didactic, explaining not only our product advantages but also helping customers decipher which model is going to be most suitable for their products. With wood, there is more extensive standardization, it is simpler. There is a wooden pallet that can be used for each application. In contrast, because plastic is more expensive initially, you must choose which is the model that will last the longest or give you the best performance for the application that you want to give it. We focus on offering innovative solutions.

What are some of your more notable products?

We have received numerous awards, especially for those innovative models we have launched during the last few years. Our half-pallets were awarded because of their repairability and the Eurosize nestable pallet with runners because it is a model that allows you to optimize your logistic and storage costs. We call it the SMART model, which received a World Packaging Award in 2016 as well as various other prizes.

We focus on innovative products and then on after-sales support; the whole process. This is what makes the difference. We are a very dynamic team and a flexible company. We take care of everything from the design of products if necessary to the sale of a product in our catalog to the recovery and recycling of the product at the end of its useful life.

Our goal is to establish long-lasting relationships with our customers!