If this is your company, CONTACT US to activate Packbase™ software to build your portal.

As they are specially manufactured with the aim of covering the specific needs of the chemical sector, the function of the pallets is based on transporting containers with liquids, products, octabins, drums, barrels, boxes or gig-bags, which contain powders and other fine materials in granular form.

As explained in previous articles, pallets are the perfect solution, both for the transportation and for the storage of all types of products, and that since the XX century until today have evolved and improved a lot, accordingly to the needs of the different industrial sectors. Considering that, not all pallets are the same; the sector of use, the circuit or the type of load for example are some of the factors that will determine the type of pallet needed.

One of the sectors that for the type of cargo and circuits has different types of pallets defined is the Chemical Industry, which, due to the very specific characteristics that define it in comparison to other sectors, require very specific pallets and that we will talk about in the following lines.

The origin of chemical pallets or CP

Considering that the Chemical Industry requires special care, as a result of the danger that it can entail for the environment, both in its processes, components and the transport its delicate products. This means that this industry needs solutions that not only reinforce the quality of its products, but also guarantee, safety, hygiene and above all environmental protection and the own cargo.

To solve this, the sector has always used the so-called chemical pallets or CP pallets. These are wooden pallets, which were originally manufactured to be used in this sector in Europe. The CP, name that comes from the English term (Chemical Pallets), are different from the most common pallets because of its wide range, classified from CP1 to CP9, by size and type of construction.

Other more efficient and sustainable alternatives

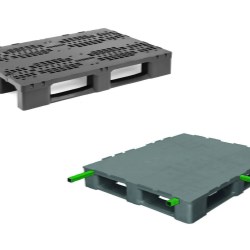

Despite the standardized use of wooden chemical pallets, in recent years, companies have begun to replace these pallets with plastic pallets to transport and store their products. Being a material much more durable, hygienic, sustainable and strictly complying with the required quality standards, there are many advantages that its use presents compared to the usual wooden CP.

- They are lighter.

- More resistant, stable and more durable.

- Waterproof and hygienic.

- Easy to clean and maintain.

- Recyclable and sustainable material.

- They save space and costs.

What are the applications and uses of the CP?

As they are specially manufactured with the aim of covering the specific needs of the chemical sector, their main function is based on transporting containers with liquids, products, octabins, drums, barrels, boxes or big-bags, which contain powders and other fine materials in granular form.

But do we know what are the alternatives in plastic to the CP?

- CP1 pallet and CP6 pallet. The two are mainly used to transport bags and boxes. The size of both pallets is 1200 x 1000 mm. Their differences are that the CP-1 has 3 runners while the CP-6 has a perimetric runner. It is most often used when stacking, due to its lower circumferential cover and, therefore, to a more even distribution of the load. The equivalent models which we produce in Nortpalet are the LOGIC 1210-G3 and LOGIC PRO 1210-G3 for the CP1 and the LOGIC 1210-G5 and LOGIC PRO 1210- G5 for the CP6. For more demanding loads and / or closed circuits where the pallet will have a long-life cycle models EXPERT 1210-O3 as CP1 and EXPERT 1210-O5 and EXPERT 1210-O6 as CP6 are available.

- CP4 pallet and CP7 pallet. This type of pallets is mainly used to transport products in bags. The size of both is 1300 x 1100 mm. Here the difference is in the lower platform, since the CP4 has 3 lower slats while the CP7 is formed by perimetric slats, also known as crowns. In this case, Nortpalet is one of the few manufacturers that has plastic pallets with similar characteristics which are in the case of the CP4, the LOGIC 1311- G3 and LOGIC PRO 1311-G3, models with 3 runners, and for the CP7, the LOGIC 1311-G5 and LOGIC PRO 1311-G5 that have 5 perimetric runners.

More and more Chemical Industry companies are looking for alternatives that are as effective as CP wooden pallets, that also add value to their products. Therefore, plastic pallets are becoming an increasingly more valued option due to their sustainable and ecological nature.