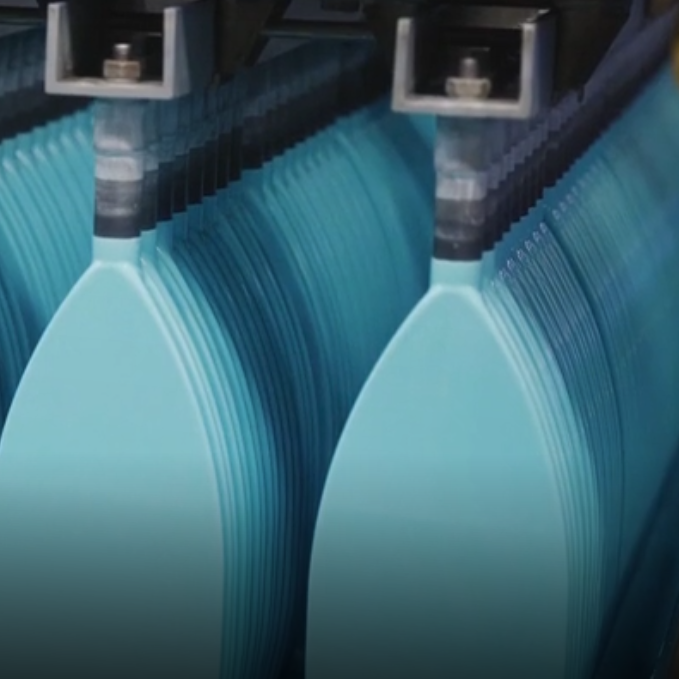

Nolato manufactures products in both natural latex and synthetic latex materials using automated production systems in Class 8 cleanroom and hygiene room environments. Dip molding technology offers unique product design possibilities. Based on extensive experience in prototyping and production techniques. Nolato is one of the largest producers of dip-molded anesthesia breathing bags in the world.

Nolato has a modern and highly automated production line, which ensures consistent high quality as well as significant capacity. In-house expertise, Nolato has the know-how and technology to produce high-quality flexible, airtight liquid latex products. Complex components can be dipped easily due to the materials' high elasticity. In-house prototype tools mean low tool investment costs and short lead times.

The company processes both synthetic and natural latex rubber. Both Nolato materials and customer-specific formulations are available. Also, there is an extensive offering of dipped standard products, such as breathing bags and premium catheter balloons, and a wide range of customized dipped components for medical customers with stringent demands.

.png)

.png)

.png)