Public

Nordson EFD Catalog

Nordson EFD Catalog for Animal Health Solutions

Nordson EFD Certificates

Nordson EFD Links

Nordson EFD Locations

Nordson EFD News

Nordson EFD Videos

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

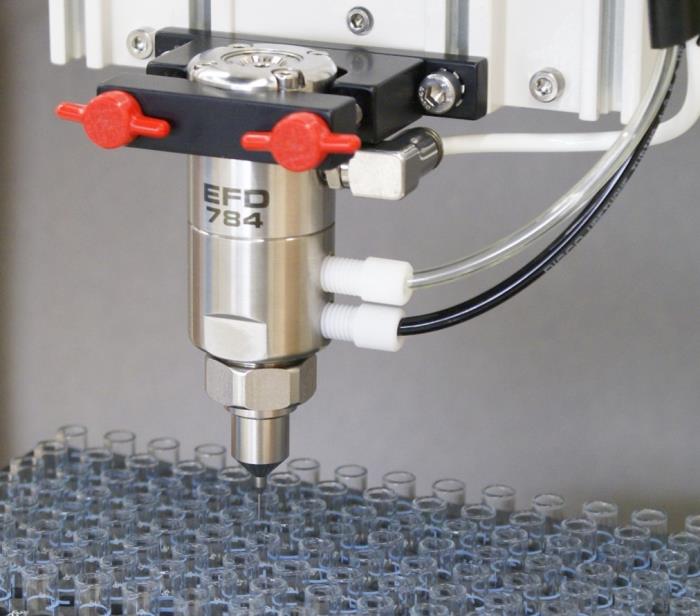

The 784S-SS aseptic micro spray valve, with FDA-compliant wetted parts, features a fluid flow path free of entrapment areas, ideal for sterile applications often required by the healthcare, pharma and medical industry.

Key features

- Easy to clean or sterilize n place

- FDA-compliant wetted parts

- Low-maintenance design

- Positive shutoff, no seals

Using Low Volume Low Pressure (LVLP) technology, the 784S-SS valve produces uniform spray patterns between 3.3 mm (0.13”) and 19.1 mm (0.75”) in diameter. It accurately controls the application of most low- to medium-viscosity fluids. For wider coverage, the 784S-SS-F model includes a fan air cap.

Its innovative design replaces a standard spray nozzle with a small gauge disposable dispensing tip, which concentrates the LVLP air used to atomize coatings into smaller spray patterns.

A fluid flow path that is free of entrapment areas makes the 784S-SS valve ideal for sterile or aseptic fluid applications. In addition, all wetted parts are 316L stainless steel and PFTE, making them suitable for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes.

Compatible fluids with the 784S-SS aseptic spray valve are:

- Saline solutions

- Stent coatings

- Silicone oils

- Solvents

The video shows 784 Aseptic Spray Valve Coating Medical Vials.