If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Realize the packaging for a total quality brand as Coop Italia is the result of a successful control and valuation process that go beyond the technical aspects and technological. It means being a ring of one of the examples of excellence of “controlled supply chain” in Europe.

Nuceria exceeded all protocols of a very accurate control system which provides for specific contracts, specifications and certifications to assure consumers of the products “brand” the highest standards of safety and product traceability. Being selected as a supplier is to engage in protocols that provide the ability to trace and track the “story” of each pack, from raw materials to finishes, from storage to distribution logistics procedures.

Being part of the “controlled supply chain” Coop is to engage in a relationship of close cooperation within the framework of the “Certification Control Service” that provides audits on suppliers and individuals critical of the supply chains controlled, analytical controls on both the supply chains, both on all finished products through the use of inspectors and qualified laboratories, confirmation of the aspects of performance by the test “Approved by Members”, exclusion of the PVC and other chlorinated polymers from materials that come in contact with food.

The packaging created for the “Joint fried” Coop brand, is made of polythene paper that provides excellent printability, is perfect for direct contact with food and ensures a long shelf life without resorting to the traditional inner envelope.

This type of material, in addition to being in line with the principles of biodegradability, limits the use of secondary coatings, thus reducing the overall amount of packing material, and – consequently – the total weight of the packaging. Also, the shape of the pack is designed to facilitate the containment of the costs of transport and storage, and, secondly, significantly reduce the loading time of filling machines.

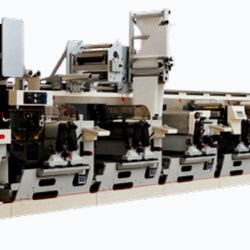

Our plants – certified BRC / IOP – apply control rules throughout the production cycle: all the materials used (cardboard, paper, polymers and additives) are certified and selected in full compliance with the regulations. We are also able to provide a biodegradable PE made to minimize the environmental impact.

The pack, therefore, is designed to ensure maximum product safety (reducing the factors of contamination and degradation).

Finally, the package includes a dispenser “Open and Close” that allows you to pour and dose the product directly, without using spoons or other utensils. A convenient system for the dosing dispenser which reduces the waste of the product and makes it storable even after opening, without the need to transfer the contents. Thanks resealable dispenser incorporated in the pack, in addition, the consumer will contact only with the dose of product that will consume, thus obtaining additional collateral from the point of view of hygiene and preservation.