Public

Packaging Innovations Birmingham Events

Packaging Innovations Birmingham Locations

Packaging Innovations Birmingham News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

At this year’s Packaging Innovations event, show organiser, Easyfairs, shortlisted ten exhibitors for their innovative packaging designs. New show feature, The Innovative Showcase, revealed these winners, at Birmingham’s NEC on 24 & 25 February, highlighting the very best within the packaging and print industry.

Prior to the show, Easyfairs, asked exhibitors to enter their latest packaging innovations, which were whittled down to a top ten shortlist, and highlighted in the show guide, giving visitors the chance to see these thought-provoking designs live on the showfloor.

The Innovation Showcase winners included:

Pulse Flexible Packaging for its unique concept, the Coca-Cola Bow. The metalised laminate is surface printed gravure by Pulse Flexible Packaging, laminated and perforated by Eshuis, before being returned to Pulse Flexible to be finished. It works by pulling away part of the label in the middle to reveal a small lever; this opens up into three parts, forming four loops that are pulled tightly to the side of the bottle to form the show stopping bow.

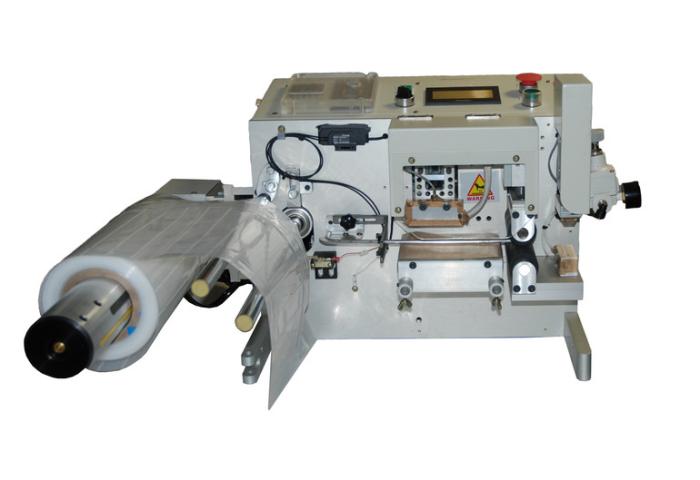

TSS Technology for its Microperflex unit, designed for the accurate measurement of the combined area of the laser micro holes (around 50/60 microns each). High tech flexible packaging companies, using this technology, need to know the exact total area of the of the perforations to enable the rate of release of the gas to be calculated, so it can gauge how long an item will stay fresh. It has a life expectancy of over 5 years and costs around 57 pence per hour, calculated on a 40-hour week.

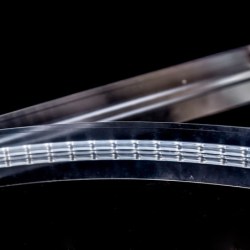

Plasfilms were shortlisted for SenzoZIP, a re-closable zipper that provides both sound and sensation when closing. An addition to the SANZIP range of products, manufactured by C.I Kasei (CIK), the leading Japanese manufacturer of reclosable zipper products, the innovation combines both audible characteristics and tactile sensation together with an excellent inner holding force and easy close features. Available as a double or triple type zipper and manufactured in LDPE.

Qualvis had two entries shortlisted in The Innovation Showcase. The first was its In-Flight Tray, designed to give a premium ‘gift’ feel to the usual ordinary in-flight meal or plastic snack trays. The tray is fully recyclable and printed using low migration inks to ensure food compatibility. Distinctive branding opportunities give the ability to use high end finishes. The second entry was Qualvis’ Qube, which is a one-piece flat folding, auto erecting patented carton tube design.

Aperture’s Irremovable Closures, for its new Irremovable Cap Closure, comprising of an aperture incorporating a one-way valve moulded as a single component. It allows a tube to be inserted through its aperture to extract the liquid contents, by way of vacuum from within a container.

Castle Colour for its, Panna-Pack, a solid board barrier, which prevents grease ingress into board and prevents discolouration and saturation. It has been used to manufacture packaging such as cartons and ‘U’ cards that are in direct contact with bakery food products. It can also be used in a Litho printed packaging environment. It is currently offered in two versions - ‘Rustic’, which is uncoated on the print side and ‘Glazed’, which is coated on the print side.

RPC Promens entered its EM Pharma Custom Contact Lens Bottle, a new bottle design to assist those who wear contact lenses, incorporating a removable contact lens cleaning and storage case. The 200ml bottle is produced in injection stretch blow moulded PET, with an injection-moulded nozzle and cap. The removable lens case is produced in injection moulded polypropylene.

Kite Packaging, were shortlisted for its Auto Airshock machine, which runs up to 480 cushions per hour. This machine significantly reduces labour and increases the amount of Airshock packs inflated. It is designed to run a range of different sized Air Shock bags and flat sheets, all of which come pre-configured and perforated on a roll, making it simple and easy to use. Airshock is coextruded polyethylene, this process of extruding two or more materials together ensures maximum strength.

Ragbags were selected for its revolutionary reusable shopping bag, uniquely designed to be repurposed as a rag. These bags are made from bio-based cellulose/Cotton spunlaced non-woven fabric and are both super absorbent and BPI certified compostable. The cotton is recycled from T-Shirt trimmings, and gives the bag a nice feel. One Ragbag can absorb 8.4 times as much liquid as a standard paper towel, plus unlike reusable bags made from plastics, it is plant based and degradable.

Seufert presented its Stone film, which is manufactured from 100 per cent waste and recycled material. It contains up to 60–80 per cent rock powder (calcium carbonate), which occurs as residual product in the building industry and in quarries. The remaining material is recycled polyethylene, which bonds the calcium carbonate. Seufert manufactures folding boxes from stone film. The white material is as stable as the usual PET film and may be decorated with offset and silk screen printing.

The next Easyfairs packaging event will be Packaging Innovations & Luxury Packaging London, which takes place at London Olympia on 14 & 15 September 2016.

.jpg)

.jpg)