Public

Packaging Decorations

Preco Corporation 3D Catalog

Preco Corporation Locations

Preco Corporation News

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

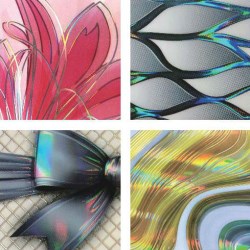

IMD (In-Mold Decoration) is composed of pre-printed motif, glue and release layers on PET carrier film just like Heat Transfer Film. IMD Motif is decorated at the same time of injection molding of plastic resin while Heat Transfer Film is decorated on finished objects. It is one of the latest and most effective decoration methods for 3D shaped products such as automobile and consumer-electronics parts. Decorating at the same time of the injection molding process, motif becomes a part of the object and no need to worry about adhesion.

The idea of IML (In-Mold decoration Label) is very similar to IMD film. It is also decorated during the injection molding process and only difference is that IML is cutout label while IMD is printed on rolled based film. IML is popular for food/ beverage industry, personal care products, etc.

ADVANTAGES

Safe and environment-friendly

IMD/IML is safe and environment friendly decoration. It can be a replacement of lacquer, spray or any other coating method.

Low emission process (environment friendly)

A dry, solvent-free process assures you low emission production process.

Realization of 3D decoration

Direct transfer of motifs to 3D shaped objects.

High productivity

Simultaneous injection molding and decoration process bring high productivity (and high physical resistance).

APPLICABLE OPTION

We can also print UV hard-coat layer on the film. By setting up an optional "UV Curing unit" on your machine, UV coating can be made at the same operation.