If this is your company, CONTACT US to activate Packbase™ software to build your portal.

The ten-year excellent working relationship that exists between chilled foods manufacturer RF Brookes and heat sealing specialists Proseal proved vital when RF Brookes required the speedy installation of high-quality tray sealing equipment.

Part of Premier Foods, the UK’s largest food manufacturer, RF Brookes specialises in chilled ready meals. When RF Brookes recently expanded their range of ready meals, the company needed to build new production lines from scratch and commence processing within a very short timeframe.

With a need to install new tray-sealing machines and tooling, RF Brookes turned to preferred supplier Proseal.

We purchased the very first Proseal PR30 when the company started and have continued to use them since,” explains Sean Durkin, at RF Brookes. “We have always found them to be extremely reliable, both in terms of the quality of the equipment and the customer service we receive.

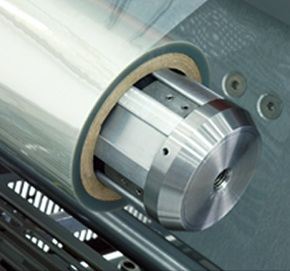

For the new meal range, Proseal supplied its latest automatic tray sealer, the GT1. Specifically developed for demanding food production environments, the GT1 is able to maintain high throughput speeds thanks to its servo-driven infeed conveyor and high accuracy tray positioning system. An intelligent film feed system provides enhanced control of the sealing operation for improved seal quality, with easy film threading and dynamic control of the movement of the film throughout the film feed cycle in order to maintain constant tension and avoid film snapping.

RF Brookes also benefits from Proseal’s pioneering Auto-Tool, which allows tool changes to be carried out in around two minutes, and the GT1’s innovative Touch Screen Control user interface, designed to optimise fast, intuitive retrieval of all recipe settings from the database. The Touch Screen can also be viewed and controlled remotely and provides detailed production data and monitoring, and full diagnostics.

RF Brookes initially ordered two GT1s for the new lines, but has subsequently doubled that figure to four. The company has been so impressed with the new machine that it is considering further purchases to upgrade other lines at its Rogerstone, Gwent factory.

A good machinery supplier is so important to a company that operates around the clock,” concludes Sean Durkin. “Proseal has always been happy to solve all of our tray-sealing needs.

.png)

Proseal America 10 year anniversary.jpg)

.jpg)

.png)

Proseal America 10 year anniversary.jpg)

.jpg)