If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Innovation has been embedded on our vision and values since we first started back in 1921.

Throughout the years, Rieke’s innovations helped companies solve problems they have encountered with their packaging suppliers.

One pain point that various food companies in the United States had, was the warping during shipping and warehousing of their food caps. In addition, many experienced increasing incidences of cross threading and line stoppages during filling line-capping operations. For that reason, Rieke’s highly qualified engineers stepped to the challenge and developed a solution, which solved companies’ issues, with their suppliers.

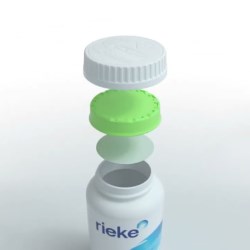

The result was Rieke’s TaperStack™ lightweight stackable caps.

Our TaperStack™ patented interlocking design feature, preserves the concentric shape of the cap. TaperStack™ cap nest together and pack as logs in the carton. Nested packing protects the shape of the closures during shipping and warehousing, improving case utilization, and ensuring the caps arrive to the filling line unwrapped. Consequently, reducing the incidences of cross threading during capping operations.

Our Taperstack™ caps are also sustainable reducing carbon footprint. Compared to traditional loose packed closures, TaperStack™ caps allow 40% more closures per case and per pallet, resulting in a 40% reduction in packaging materials, as well as freight reductions, warehouse space savings, and carbon footprint.

To learn more about our TaperStack™ range, click here.

.jpg)