Nikky Okelue, QHSE Manager, Roberts Metal Packaging, talks about the importance of quality through robust procedures in achieving the best results for customers

In any manufacturing setting, quality is a central component to success. In a robust open market with plenty of competition, quality stands out as a significant differentiator for both products and services.

Quality and compliance are both vital in meeting the needs and expectations of clients, alongside creating a more efficient and sustainable business model, and providing a strong foundation for achieving excellence in end product and service.

Many companies will engage with both quality control and quality assurance, alongside environmental and health & safety management; we spoke to Nikky Okelue at Roberts to find out more:

What is your role with Roberts?

My role with Roberts is multifaceted looking after our various Management Systems which include;

- Quality Management System (ISO 9001:2015)

- Occupational Health and Safety Management system (ISO 45001:2018)

- BRC Global Standard for Packaging Materials

- Environmental Management Systems (ISO 14001:2015).

Quality assurance is delivered by our management and supervision teams together with a small dedicated quality control team.

Why is compliance important?

Compliance establishes customer trust and brand loyalty through enhanced consistency of operational processes, quality and customer service.

Our main focus is on four specific areas:

- The quality management system focuses on our customers and helps us meet every target in the journey to meeting our customers’ expectations.

- Our Occupational H&S management system manages hazard identification and risk assessment; it also helps in reducing downtime, enhances the involvement of management, and participation from workers.

- Our Environmental Management System helps us quantify, monitor and control the impact of our operations on the environment, alongside meeting legislation, improving resource efficiency and reducing waste.

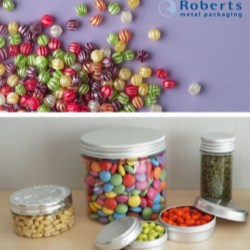

- RC Global Standard for Packaging Materials compliance is applicable to our customers in the food industry as well as customers in beauty and toiletries sectors. We often work with colour cosmetics, skincare and male grooming customers whose products have to be packaged to a very high standard, safely, hygienically in accordance with agreed specifications.

How do you ensure high quality standards?

Every stage of production and delivery is critically important to us, from supplier selection to the delivery of finished goods to our customer. From the moment we receive products from an approved supplier, we ensure it meets all internal and customer requirements, and this involves carrying out stringent quality control checks. Our quality management procedures guide us in our checks and comparisons.

During production we carry out various quality checks – aesthetic checks, design checks, specification checks. We have drawings in place alongside approved samples. We also carry out first off and last off sample checks and ensure sample comparisons are made throughout production. There are four full quality control checks made within 24 hours in addition to continuous operator monitoring.

When the goods are produced and are taken to the warehouse, the warehouse also carries out evaluations, including counting the boxes and ensuring product details on the batch label match the dispatch note labels. It’s a continuous process from the beginning, until it gets to the customer.

KPI’s covering all aspects of the delivery of customer service are recorded and analysed to ensure our standards continuously improve.

Does each product or client get a different plan?

At Roberts we have a general quality assurance plan for all products, however each product can also have its own unique plan based on customer requirements. We have numerous testing tools capable of measuring dimensions, application/removal torque, coating strength, heat resistance, colour etc.

What is the best part of your job?

Helping to deliver the very highest levels of customer service is extremely motivational and receiving positive feedback from external auditors on our systems and procedures is also rewarding. I am particularly proud that “Make UK” have used some of my work as examples of best practice for other clients. I am very pleased to be part of the Roberts Team.