Public

Robinson Capabiities

Robinson Packaging Catalog

Robinson Packaging Documents

Robinson Packaging Gallery

Robinson Packaging Innovation Videos

Robinson Packaging Locations

Robinson Packaging News

Robinson Packaging Showcase 3D Models

If this is your company, CONTACT US to activate Packbase™ software to build your portal.

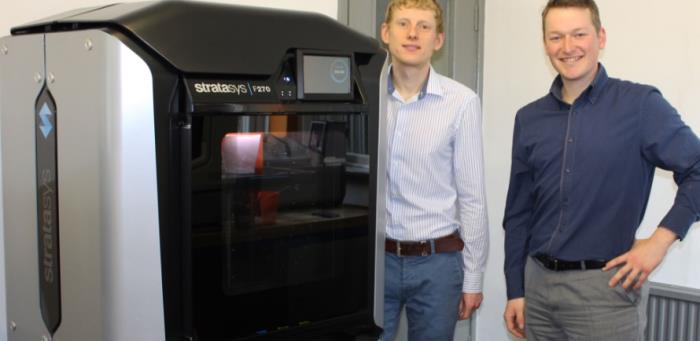

Robinson Packaging have always been quick to adopt new technology, and as part of an on-going development plan, they have invested in the latest state of the art 3D printer technology and new tool room machinery to strengthen their custom project rapid prototyping and pilot tool capabilities at their Kirkby-in-Ashfield site.

The new 5 axis CNC Hurco VM20i milling machine enables Robinson to control pilot tool manufacture with more flexibility and further supports their “continues improvement” plans for the production moulding facilities.

Given Robinson Group ethos for developing custom packaging solutions for the food, personal care and home care sectors: having in house rapid prototyping is essential to supporting the creative design team’s conceptual ideas and consequently, upgrading their 3D printing capabilities, Robinson will be the first company in Europe to take delivery of the Stratasys F270 3D printer.

This machine has proved invaluable for both functional prototyping and design refinement as it is twice as fast as its predecessor, and allows an even more efficient turnaround of design prototypes and test parts in a wider range of material options.

.jpg)