If this is your company, CONTACT US to activate Packbase™ software to build your portal.

At this year’s Pharmintech in Bologna the Romaco Group will show a flexible secondary and final packaging line from Romaco Promatic. The engineering specialists will also be demonstrating Romaco Innojet’s high-efficiency coating and granulation processes.

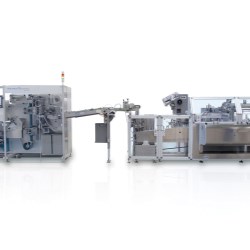

Romaco Promatic: powerful secondary and final packaging line

Romaco Promatic cartoning solutions are ideally suited for a wide range of applications and provide high flexibility when it comes to bespoke feed options for products, instruction leaflets and inserts. At the upcoming Bologna exhibition Romaco will show its Promatic PC 4300 high speed, continuous motion cartoner in line with the Promatic PAK 320 case packer for packing vials into cartons and cases. Both machines are equipped with a servo controlled positive carton and case pick-up and opening system. This patented system ensures extremely gentle handling of the packaging regardless of the carton material. The line is configured with a GMP compliant balcony structure in keeping with the Promatic philosophy.

The retractable carton magazine of the Promatic PC 4300 cartoner, for instance, facilitates access to all cartoner components, speeding up retooling and cleaning significantly. Reproducible and tool-less format changes are completed in under 15 minutes. Brushless motors and belt drives guarantee low vibration and noise levels. The Promatic PC 4300 achieves a mechanical speed of up to 320 folding cartons a minute. Various integral control mechanisms check the quality of the secondary packaging processes – only positively separated, good packs are then transferred to the Promatic PAK 320.

Once the cartons have been transferred to this fully automatic, side-loading case packer, they are grouped, stacked and packed in shipping cases. Various inspection systems, all of which are easily accommodated, in the line, enable quality control and track & trace. The folding cartons are identified layer by layer to allow tracking of individual packs. The Romaco Promatic PAK 320 achieves a maximum overall output of eight cases per minute, with a choice of either hot melt or adhesive tape closure.

Romaco Innojet VENTILUS® V 2.5: all-rounder for granulation and coating

The internationally patented Romaco Innojet technology is based on the air flow bed method originally developed by Dr. h.c. Herbert Hüttlin. The VENTILUS® V 2.5 granulates and coats products for the pharmaceutical, food and chemical industries. The laboratory-scale machine in particular processes particles from 10 µm to 30 mm in diameter. This versatile technology is hence suitable for trials with powders, granulates, pellets, tablets, capsules and other free-flowing bulk materials such as catalysts. The enhanced processing efficiency of the Romaco Innojet VENTILUS® V 2.5 permits up to 25% shorter batch times. The homogeneous flow conditions inside the cylindrical product container enable extremely gentle intermixing of the batch. The process air is controlled by the ORBITER booster, an ingenious container bottom consisting of overlapping circular plates. Together with the ROTOJET, the central bottom spray nozzle, the booster forms an innovative functional unit that meets all the requirements for linear scale-ups. The air flow bed technology ensures accurate control of the product movement and equally precise application of the spray liquids. The resulting formulations can achieve the required release profile with between 10 and 15% less spray liquid.

On show at Pharmintech in Bologna/Italy from April 13 to 15, 2016 (Hall 22, Stand A5).

.jpg)