If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Retrofit ensures long-term process reliability

At the upcoming Nuremberg exhibition Romaco Kilian will present an innovative retrofit package which enables older-generation tablet presses to be upgraded electronically. The manufacturer will also show the versatile, high speed Kilian KTP 420X press with its convincing new design concept “cool, fast & clean”.

Romaco Kilian retrofit: electronic upgrade to the state of the art

A new retrofit concept, to be unveiled at the Nuremberg Powtech 2016, is offered by Romaco Kilian for selected older-generation tablet presses. This innovative solution strategy was born from the realisation that some of the control and regulating components featured in the Kilian E 150 (Plus), LX, RTS, RX, S 250 (Plus), T 100, T 300, T 400 and TX series are no longer compliant with current standards. The comprehensive electronic upgrade developed by Romaco Kilian enables customers to prolong the life of these otherwise extremely reliable tablet presses for several more years. An external electrical cabinet and a modern, intuitive HMI panel are integrated as part of the new retrofit package. The installation and validation can be performed directly at the customer’s facility, saving time and money and reducing downtime to a minimum. The mechanical components can be overhauled at the same time. Manufacturers who opt for this upgrade to the latest state of the art can hence profit for much longer from highly reliable processes on their Kilian tablet presses. They can also take advantage of “Remote Assist”, Romaco’s new online support system. A remote online support case is activated on the machine at the push of a button, immediately setting up a connection to a Kilian expert.

Romaco Kilian KTP 420X: cool, fast, clean

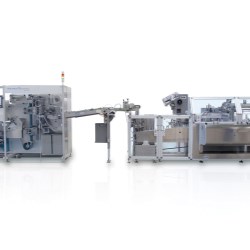

Cool, fast, clean – these three hallmarks of the Romaco Kilian KTP 420X tablet press are attracting considerable attention among pharmaceutical manufacturers worldwide. “Cool” stands for the reliable cooling of the process area to below 30°C, which is why the technology is ideal for processing temperature sensitive medications such as Ibuprofen or Metformin. Special compression rollers, bolts and bearings ensure low mechanical friction while the efficient cooling of the V-ring seals and drives prevents the formation of heat. “Fast” denotes the high speed – and specifically the maximum output of 360,000 tablets per hour. “Clean” refers to the optimised hygienic design, which improves product quality and makes the process more reliable. The hermetic separation of the compaction area and the machine compartment means no tablet dust gets into the bottom of the machine. The patented punch bellows protect the tablets from contamination with lubricants. The die-table, tablet chute and fill shoe can be swung right in or out, so that fewer adjustments are needed for cleaning. Changing the product or format is easy because no special tools are required. Thanks to the ingenious design, cleaning work is restricted to a minimum.

Romaco Kilian’s KTP 420X high speed tablet press particularly impresses with its excellent OEE (overall equipment effectiveness) and TCO (total cost of ownership) values. The press can optionally be supplied with the integrated CWC (Continuous Weight Control) system. All in all, the technology is incredibly versatile: the special effervescence concept developed by Romaco Kilian, for example, allows fragile effervescent products to be processed very reliably. There is no risk of breakage or dust when the effervescent tablets are transferred directly to the primary packaging machine installed downstream.

On show at Powtech in Nuremberg/Germany from April 19 to 21, 2016 (Hall 3, Stand 3-430).

.jpg)