If this is your company, CONTACT US to activate Packbase™ software to build your portal.

Romaco Macofar MAC 2: next-generation capping machine

The upcoming P-MEC is Romaco’s chosen platform to unveil its new Macofar MAC 2 intermittent motion capping machine. This technology is ideal for closing cylindrical glass vials that have been filled with sterile pharmaceutical powders or liquids. After inserting the rubber stoppers, the vials are transferred to the MAC 2, which seals them with flip-off closures or simple alu-caps. The MAC 2 is built with two closing heads for a maximum output of 12,000 vials per hour. The vials to be capped are positioned one by one on rotating bases and held there firmly from above. Idle blades which are in charge of the sealing process are equipped with springs to compensate the minimal differences between the vials within one batch. This kind of individual sealing reduces friction and prevents the generation of aluminum particles – a clear advantage compared to capping by means of a single fixed blade, especially when it comes to meeting cGMP requirements.

The capping pressure is set via the HMI panel. Two built-in load cells verify this pressure on each individual vial. This method provides an accurate indication of the stoppering quality. In case of any deviations from the defined tolerance range, the vials concerned are automatically removed. The Macofar MAC 2 complies with all established guidelines and regulations for aseptic processes. With its strictly ergonomic design, the machine is very easy to retool, clean and operate.

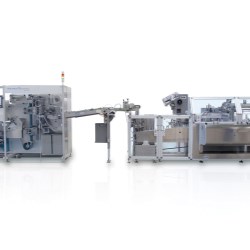

Romaco Noack 921 blister line: compact solution for many applications

Romaco’s compact blister line, with the Noack 921 rotary sealing machine and the Promatic P 91S intermittent motion cartoner, is extremely reliable and suited for a wide range of applications. Short cleaning times, quick format changes and an advanced level of automation are the hallmarks of this cGMP compliant blister system. With an output of up to 400 blisters per minute, the Romaco Noack 921 blister line is predestined for small to medium batch sizes. The fully interchangeable QuickFeed unit enables product changes to be completed in next to no time. While one module is being cleaned, the production of the next batch can continue directly with the other unit. Significantly higher OEE values, which are a measure of the overall equipment effectiveness, are realised in this way. Furthermore, the integral servo technology provides reproducible processes and speeds up retooling on the machine. QuickAdjust – the automatic station control system – adjusts the sealing, coding and perforation processes. The run-in times after changing the product or packaging are consequently much shorter.

The blisters are de-stacked and passed to the cartoner’s bucket chain in a very small space. In the high-speed version, the Promatic P 91S intermittent motion cartoner achieves a maximum output of 140 cartons a minute. Its cGMP compliant balcony architecture ensures that no supporting structure is needed on the operator side and affords a far better view of the process. Cross-contamination is effectively eliminated and line clearances greatly simplified. The cartoner’s ergonomic design with a retractable carton magazine means all components are optimally accessible, making retooling and cleaning very fast. Format changes are now possible in less than fifteen minutes.

Romaco Kilian KTP 720X: powerful double-sided rotary press

Cool, fast & clean – these three design features of the Romaco Kilian KTP 720X double-sided rotary press are attracting considerable attention among pharmaceutical manufacturers worldwide. “Cool” is a set of measures which enable the temperature in the process area to be maintained at a constant level below 30°C. Special compression rollers, bolts and bearings are used, for example, to restrict mechanical friction to a minimum. At the same time, the efficient cooling of the V-ring seals and drives prevents unwanted heat. The powerful rotary press is consequently ideal for processing temperature sensitive medications such as Metformin or Ibuprofen. “Fast” denotes the ability to speed up product changes: in order to shorten the retooling and cleaning times, the number of product-contacted format parts has been systematically reduced and access to the various components is now easier than ever. “Clean” refers to the optimised hygienic design, which improves product quality and makes the process more reliable. The strict separation between the compaction and service areas prevents tablet dust from entering the machine compartment during the production process. The patented punch bellows moreover protect the tablets from contamination with lubricants.

With a maximum output of 1,020,000 tablets per hour, the Kilian KTP 720X is classed as a high speed model. The HMI panels of this tablet press incorporate zoom and swipe navigation inspired by modern smartphones. The Romaco Kilian additionally impresses with innovative features on the operator side.

Romaco Kilian S 370 Prime: tableting solution for mid-sized batches

The Romaco Kilian S 370 Prime is designed for fully automatic production of mid-sized batches and compresses up to 330,000 tablets an hour. It offers excellent value for money and the low initial capital investment is a convincing argument for pharmaceutical manufacturers all over the world. This compact press combines several highlights such as GAMP compliant automation, an integrated lifting system to speed up die table exchanges and patented, wear-free brake magnets. Retooling and cleaning times are reduced to a minimum because easy access is possible to all components while the space efficient design means no external electrical cabinet is needed. The machine is controlled via the integrated HMI touch panel and Vicon visualisation software, so that operation is very straightforward. The Romaco Kilian S 370 Prime can be equipped with an automatic tablet tester and a trending function on request.

Romaco Kilian STYL’ONE Evolution: tableting robot for R&D applications

Romaco Kilian’s STYL’ONE Evolution tableting robot is predestined for a broad array of R&D applications and for producing very small batch sizes. With a maximum output of 1200 tablets per hour, this single-stroke press processes mono-layer, multilayer or core tablets (tab in tab). Equipped with a gravity or paddle force fill shoe, the STYL’ONE Evolution is capable of processing up to three different components and compressing tablets with as many as five layers. Any standard rotary press can be simulated thanks to ANALIS, the intelligent PAT software. The user simply selects the machine model and predefines the required tablet thickness or compression force. ANALIS then automatically determines the optimal compression parameters for the production scale. Since the necessary compression force profiles are created independently by the tableting robot, the time saving is enormous. The remarkable precision of the test batches means the powder properties can be analysed very realistically. Apart from developing new formulations, the STYL’ONE Evolution can thus also be utilised to optimise processes or troubleshoot errors. The highly efficient PAT system offers a continuous improvement in product quality.

On show at P-MEC in Mumbai (India) from November 21 to 23, 2016 (Hall 6, Booth D40).

.jpg)