Excellent application starts with unique applicators

Foamers done well - Spotlight on SR Packaging

PET The plastic twin of glass

Seduction through decoration

Spotlight on SR Packaging

SR Packaging

SR Packaging controls tube dispensing doses

SRP's toughest pumps!

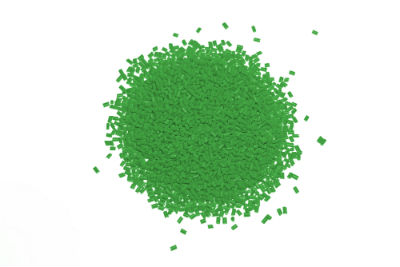

The rise of PCR plastic

SR Packaging: Spotlight on custom texturing